EXPLANATION

The determination of debris in used lubricating oils is a key diagnostic method practiced in machine condition monitoring programs. The presence or increase in concentration of specific wear metals can be indicative of the early stages of wear if there are baseline concentration data for comparison. A marked increase in contaminant element can be indicative of foreign materials in the lubricants, such as antifreeze or sand, which may lead to wear or lubricant degradation. The test method identifies the metal and their concentration so that trends relative to time or distance can be established and corrective action can be taken prior to more serious or catastrophic failure.

This test method uses oil-soluble metals for calibration and does not purport to relate quantitatively the values determined as insoluble particles to the dissolved metals. Analytical results are particle size dependent and low results may be obtained for those elements present in used oil samples as large particles.

TEST SUMMARY

Wear metals and contaminants in a used oil test specimen are evaporated and excited by a controlled arc discharge using the rotating disk technique. The radiant energies of selected analytical lines and one or more references are collected and stored by way of photomultiplier tubes, charge coupled devices, or other suitable detectors. A comparison is made of the emitted intensities of the elements in the used oil test specimen against those measured with calibration standards. The concentrations of the elements present in the oil test specimen are calculated, displayed, or entered into a database for processing.

INTERFERENCES - There could be three types of interferences in this method. Refer to Test Method ASTM D6728 for discussion on interferences.

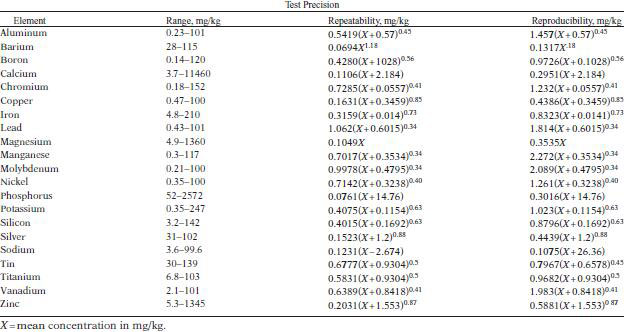

TEST PRECISION

Bias was insignificant for all elements with the exception of barium at 30 mg/kg, nickel at 50 mg/kg, and titanium at 100 mg/kg concentrations. The calculated bias values are of lesser significance in used oil trending applications.