EXPLANATION

Since petroleum wax is a mixture of hydrocarbons with different molecular weights, its transitions occur over a temperature range. This test method measures the transition temperatures of petroleum waxes, including microcrystalline waxes, by differential scanning calorimetry (DSC). These transitions may occur as a solid-solid transition or as a solid-liquid transition. The former is related to the properties of the solid, that is, hardness and blocking temperature. The second is the highest temperature transition associated with complete melting; it can guide the choice of wax storage and application temperatures.

The normal operating temperature range is from 15 - 150° C. Test Method ASTM D87 also measures energy transfer between wax and a standard environment. The highest temperature DSC transition may differ from the melting point because the two methods approach the solid/liquid phase transition from different directions. The DSC method cannot differentiate between solid-liquid and solid-solid transitions. Such information must be predetermined by other techniques. In case of blends, the lowest temperature transition may be envelopes of both solid-liquid and solid-solid transitions.

TEST SUMMARY

Separate samples of petroleum wax and a reference material or blank (empty sample container) are heated at a controlled rate in an inert atmosphere. A sensor continuously monitors the difference in heat flow to the two samples. The DSC curve is a record of this difference versus temperature. A transition in the wax involves the absorption of energy relative to the reference, resulting in an endothermic peak in the DSC curve. While the transition occurs over the temperature range spanned by the base of the peak, the temperature associated with the peak apex is designated the nominal transition temperature.

Since the sample size taken for analysis is only 10 mg, it is particularly important that the test specimen be homogenous and representative of the bulk material. Intimate thermal contact, sample-to-pan and pan-to-sensor, is essential to obtain accurate and reproducible results. The heating rate must be the specified 10 +/- 1 ° C/min. Faster or slower rates will produce a different transition temperature and transition peak width.

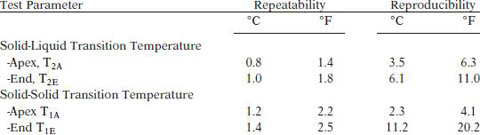

TEST PRECISION

The procedure in this test method has no bias because the value of the transition temperature can be defined only in terms of this test method.