EXPLANATION

Trace metals in turbine fuels can cause corrosion and deposition on turbine components at elevated temperatures. Some diesel fuels have specification limit requirements for trace metals to guard against engine deposits. For example, trace level copper in middle distillate aviation turbine fuel can significantly accelerate thermal instability of the fuel leading to oxidation and production of detrimental insoluble deposits in the engine. Gas turbine fuel oil Specification ASTM D2880 provides recommended upper limits for five trace metals (calcium, lead, potassium, sodium, and vanadium). Military specification MIL-16884J for naval distillate fuel sets requirements for maximum concentrations of the same five metals. Both specifications designate Test Method ASTM D3605, an atomic absorption/flame emission method for the quantitative determination of four of these metals. It does not include potassium in its scope. This test method offers an alternative to ASTM D3605 and can also determine potassium as well as several other trace elements.

There are several sources of multi-element contamination of naval distillate fuel. Sea water is pumped into the diesel fuel tanks (as ballast) to trim ships. Also, some of the oilers (fuel supply ships) have dirty tanks. Corrosion products come from unlined tanks, piping, pumps, and heat exchangers.

This test method can determine about 20 trace elements in the range 0.1 to 2.0 mg/kg in middle distillate fuels using inductively coupled plasma-atomic emission spectrometry (ICP-AES). However, the test method can be used for concentrations about this range. The middle distillate fuels covered in this test method have all distillation fractions contained within the boiling range of 150 to 390° C. This includes, but is not limited to, diesel fuels and aviation turbine fuels. This test method is not intended to analyze insoluble particulates. However, very small particulate matter (smaller than 1μ) will be carried into the plasma and be included in the quantitative analysis. This test method may give a result that is higher than the true value if an analyte is present in the sample in a form which is sufficiently volatile. For example, hexamethylsiloxane will generate a biased high result for silicon.

TEST SUMMARY

Calibration standards are prepared by mixing organometallic standard materials in kerosene. An internal standard material is added to both the calibration standards and the fuel samples. The calibration standards and the fuel samples are aspirated into the ICP-AES instrument. The concentrations of the elements in the fuel are calculated by comparing emission intensity ratios of the fuel and the calibration standards to the internal standard.

INTERFERENCES - The elemental wavelengths listed in the test method have been found to be free of spectral interference. If a spectral interference does exist, then selecting an analytical wavelength other than the ones listed in the test method may be used as long as the new wavelength possesses appropriate sensitivity for the scope of the method. Alternatively, the ICP spectrometer manufacturer's software may be used to provide corrections to interferences that cannot be avoided by wavelength selection and background correction. An empirical method of correcting for spectral interferences is detailed in Test Method ASTM D5185.

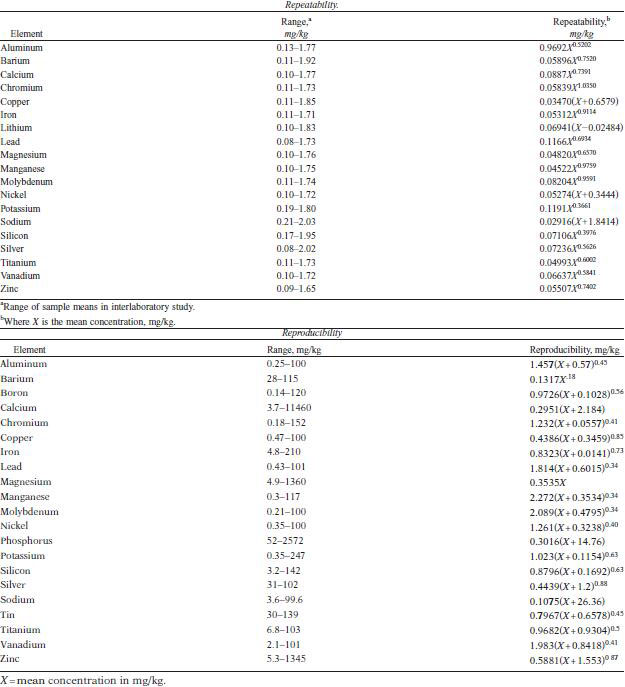

TEST PRECISION

Since there is no accepted reference materials for determining bias for this test method, no statement on bias is being made.