EXPLANATION

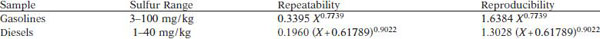

This test method covers the determination of total sulfur in liquid hydrocarbons (e.g., naphthas, distillates, reformulated gasolines, diesels, biodiesels, and motor fuels) boiling in the range from approximately 25 - 400° C, with viscosities between approximately 0.2 and 10 cSt at room temperature, and containing approximately 1 - 100 mg/kg of total sulfur in gasoline type products, and approximately 1 - 40 mg/kg in diesel type products. The detector response for this technique within the scope of this test method is linear with sulfur concentration. The pooled limit of quantitation of this method is 3 mg/kg for gasoline and <0.5 mg/kg for diesel samples. This test method is equivalent to Test Method ASTM D6428 which was at one time designated by U.S. EPA as the preferred method for determination of ultra low sulfur in diesels.

TEST SUMMARY

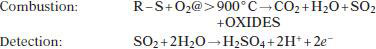

The sample is injected at a controlled rate into a stream of inert gas (helium or argon) or inert gas mixed with oxygen. The sample is vaporized and carried into a high temperature zone (>900° C) where oxygen is introduced. Sulfur compounds, present in the specimen are converted to SO2. This is reacted with the sensing electrode in a 3-electrode electrochemical cell. This reaction produces a measurable current that is directly proportional to the amount of sulfur in the original sample. The reactions that occur are as follows:

INTERFERENCES - Moisture produced during the combustion step can interfere if not removed prior to the detector. Equivalent amounts of nitrogen in the sample may also interfere.

TEST PRECISION

Where X is the average of two sulfur results in mg/kg.

Based on the analyses of NIST Standard Reference Materials, there was no significant bias for the test method.