EXPLANATION

Low levels of sulfur in process feed stocks can poison expensive catalysts used in petroleum refining processes. This test method can be used to determine total sulfur levels in these process feeds and finished products that fall within the scope of this method. This test method covers the liquid hydrocarbon samples with a final boiling point less than 450° C (such as motor fuels and oils) by gas chromatography using a flame photometric detector. This test method is applicable to total sulfur levels from 0.5 to 100 mg/kg of sulfur. The pooled limit of detection is determined to be 1 mg/kg. Samples can also be tested at other higher levels.

TEST SUMMARY

A fixed amount of sample is injected into the gas chromatograph where it is vaporized. The air carrier stream carries the vaporized sample into a high temperature zone (>900° C) where the compounds present in the sample are oxidized. Sulfur compounds are converted to SO2. The carrier stream carries the oxidation components onto a chromatographic column where they are separated, and the SO2 is quantified by the flame photometric detector. Calibration of the detector is achieved by the use of an appropriate external standard.

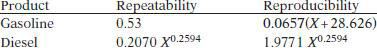

TEST PRECISION

Where X is the mean of results. All values are in mg/kg of sulfur.