EXPLANATION

Some process catalysts used in petroleum and chemical refining may be poisoned when trace amounts of sulfur bearing materials are contained in the feedstocks. This test method can be used to determine sulfur in process feeds and may also be used to control sulfur in finished products.

This test method covers the determination of total sulfur in liquid hydrocarbons, boiling in the range from approximately 25° C to 400° C, with viscosities between approximately 0.2 and 10 cSt (mm2/S) at room temperature. This test method is applicable to naphthas, distillates, motor fuels oils, engine oils, ethanol, FAME, and engine fuels such as gasoline, RFG, diesel, biodiesel, and jet fuel containing 1.0 to 8000 mg/kg total sulfur. The pooled limit of quantitation ranges from <1 to <5 mg/kg depending on the matrix being analyzed.

This test method is applicable for total sulfur determination in liquid hydrocarbons containing less than 0.35 mass % halogen(s).

The pooled limit of quantitation ranges from <1 to <5 ppm depending on the matrix analyzed.

TEST SUMMARY

A hydrocarbon sample is directly injected or placed in a sample boat. The sample or boat, or both, enters into a high temperature combustion tube where the sulfur is oxidized to sulfur dioxide (SO2) in an oxygen rich atmosphere. Water produced during the sample combustion is removed and the sample is next exposed to ultraviolet (UV) light. The SO2 absorbs the energy from the UV light and is converted to excited sulfur dioxide (SO2). The fluorescence emitted from the excited SO2 as it returns to a stable state is detected by a photomultiplier tube and the resulting signal is a measure of the sulfur contained in the sample.

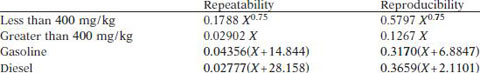

TEST PRECISION

Where X is the mean result in mg/kg.

This test method has no bias based on the analysis of standard reference materials.