EXPLANATION

Insoluble material may form in oils subjected to oxidizing conditions. This test method is used to evaluate the tendency of inhibited mineral oil based steam turbine lubricants and mineral oil based anti-wear hydraulic oils to corrode copper catalyst metal and to form sludge during oxidation in the presence of oxygen, water, and copper and iron metals at an elevated temperature. The test method is also used for testing circulating oils having a specific gravity less than that of water and containing rust and oxidation inhibitors. Significant formation of oil insolubles or metal corrosion products, or both, during this test may indicate that the oil will form insolubles or corrode metals, or both, during field service. However, no correlation with field service has been established.

This test method is a modification of Test Method ASTM D943 where the oxidation stability of the same kind of oils is determined by following the acid number of oil.

TEST SUMMARY

An oil sample is contacted with oxygen in the presence of water and iron-copper catalyst at 95° C for 100 h. The weight of the insoluble material is determined gravimetrically by filtration of the oxidation tube contents through a 5 μm pore size filter disk. The total amount of copper in the oil, water, and sludge phases is also determined.

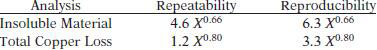

TEST PRECISION

This precision statement is based on the samples in the range of 4.6 to 250 mg insoluble material, and 0.9 to 30 mg total copper.

This procedure has no bias.