EXPLANATION

Control over the residue content (required by Specification ASTM D1835) is of considerable importance in the end-set applications of LPG. In liquid feed systems the residues may lead to troublesome deposits and, in vapor offtake systems, residues that are carried over can foul regulating equipment. Those that will remain will accumulate, can be corrosive, and will contaminate following product. Water, particularly if alkaline, can cause failure of regulating equipment and corrosion of metals. This test covers the determination of the extraneous materials weathering above 38° C that are present in liquefied petroleum gases. LPG that contain alcohols to enhance their anti-icing behavior can give erroneous results by this test method. The results can be expressed in terms of measured volumes or indices derived from these volumes. In either case, the test method provides an indication of the quantity and nature of materials in the product that are substantially less volatile than the LPG hydrocarbons.

Although this test method has been used to verify cleanliness and lack of heavy contaminants in propane for many years, it may not be sensitive enough to protect some equipment from operational problems or increased maintenance. A more sensitive test, able to detect to lower levels of dissolved contaminants, may be required for some applications.

TEST SUMMARY

A 100 mL sample of LPG is weathered in a 100 mL centrifuge tube. The volume of residue remaining at 38° C is measured and recorded as is also the appearance of a filter paper to which the residue has been added in measured increments.

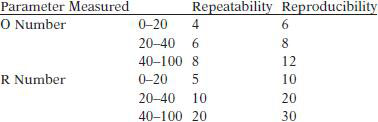

TEST PRECISION

The procedure in this test method has no bias because the residues are defined in terms of this test method.