A1.1.1 Syringes, fixed needle gas-tight, of suitable size, and a rubber slip-on septum.

A1.1.2 Vacuum Pumping System, capable of evacuating the glassware to an absolute pressure of 1 x 10(-3) torr (130 mPa) or lower.

A1.1.3 Erlenmeyer Vacuum Flask, 1-L with a glass inlet tube, capable of being evacuated through a vacuum pump, containing a PTFE-coated magnetic spin bar, and a magnetic stirrer.

A1.1.4 Gas-Tight Chromatography Syringe, 2.0 mL.

A1.1.5 Lab Bench Vacuum Pump, small, attached to 6 in. piece of vacuum tubing containing a needle end.

A1.2 Procedure

A1.2.1 Using a 1-L Erlenmeyer flask attached by vacuum tubing to a mechanical vacuum pump, degas approximately 500 mL of clean oil by stirring the oil under vacuum with a TFE-fluorocarbon stir bar and magnetic stirrer for approximately 2 h, or until no more noticeable air is being drawn out of the oil.

A1.2.2 Rapidly transfer 75 mL of the "blank oil" from the flask to a gas-tight pre-calibrated 100-mL syringe containing a Luer lock valve, breaking vacuum with the same gas as the carrier gas. Air can be used to break vacuum if there is sufficient oil to determine a baseline for oxygen, nitrogen, and carbon dioxide for each syringe. Expel any bubbles that might be present.

A1.2.3 Using the blank oil, determine the quantity of remaining gases in the oil by analyzing an aliquot of the oil from the gas-tight syringe. The 75 mL initial volume provides enough volume for this analysis to be repeated (in some cases 2 or 3 times) to ensure repeatable results.

A1.2.4 Adjust the oil volume in the syringe to 50 mL by holding the syringe vertically with the tip pointed upwards and insert a slip-on septum on the tip of the syringe.

A1.2.5 Turn the syringe so that the tip is facing downward, and inject 1.0 mL of the high-concentration gas standard taken under known conditions of temperature and pressure into the blank oil through the septum seal contained on the syringe valve. If the "high" gas standard is taken from a pressurized container, the syringe should be filled to capacity and then allowed to bleed down slowly to atmospheric pressure before adjusting to the desired volume. Rapid decompression of a gas sample results in adiabatic cooling leading to an unknown temperature of the gas sample. Record ambient temperature and for use in calculating the concentration of the gas-in-oil standard. The injection is performed using a 2.50 mL gas-tight syringe.

A1.2.6 Shake the syringe with a back and forth motion, while applying a slight positive pressure with the syringe barrel, until the bubble containing gas standard is completely dissolved. The use of a thin, flat washer can facilitate the stirring action and aid in homogenizing the sample.

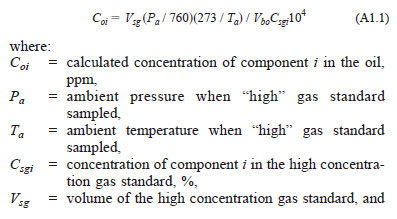

A1.2.7 Determine the calculated concentration of the gases dissolved in the standard as follows: