EXPLANATION

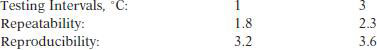

See explanation in Test Method ASTM D6749 earlier. Test results from this method can be determined at either 1 or 3 ° C intervals. This test method yields a pour point in a format similar to Test Method ASTM D97, when the 3 ° C interval results are reported. This test method has comparable repeatability and better reproducibility relative to Test Method ASTM D97. In this test method the automatic instrument tilts the test jar to detect surface movement of the test specimen with an optical device, after being removed from a regulated, stepped-bath cooling jacket. This test method is designed to cover the temperature range of -57 to +51° C. This test method is not intended for use with crude oils, nor its applicability has not been verified for residual fuels.

TEST SUMMARY

After insertion of the specimen into the automatic pour point apparatus and initiation of the testing program, the specimen is heated and then cooled according to a prescribed profile.

The specimen surface is examined periodically for movement using an optical camera system mounted on top of the specimen test jar, while tilting the specimen test jar. The test jar is removed from the jacketed cooling chamber prior to each examination. The lowest temperature, when movement of the surface of the specimen is detected, is recorded as the pour point.

TEST PRECISION

When testing at 3 ° C intervals, relative bias among certain samples was observed versus results from Test Method ASTM D97.

The relative bias was not a fixed value but appeared to be a linear function of the pour point value. When measuring at 1 ° C intervals, a bias of 1.1° C on the average was observed against Test Method ASTM D97.