EXPLANATION

Gasoline-range olefinic hydrocarbons contribute to photo-chemical reactions in the atmosphere, which result in the formation of photochemical smog in susceptible urban areas. The California Air Resources Board (CARB) has specified a maximum allowable limit of total olefins in motor gasoline. This test method compares favorably with Test Method ASTM D1319 (FIA) for the determination of total olefins in motor gasolines. It does not require any sample preparation, has a comparatively short analysis time of about 10 min, and is readily automated. The application range is 1 - 25 mass % of total olefins. This test method can be used for analysis of commercial gasolines, including those containing varying levels of oxygenates, such as methyl tert/butyl ether (MTBE), diisopropyl ether (DIPE), methyl tert/amyl ether (TAME), and ethanol, without interference. This method has not been designed for the determination of the total amounts of saturates, aromatics, and oxygenates. Alternative methods for determination of olefins in gasoline include Test Methods ASTM D6293 and ASTM D6296.

TEST SUMMARY

A small aliquot of the fuel sample is injected onto a set of two chromatographic columns connected in series and transported using supercritical carbon dioxide as the mobile phase. The first column is packed with high-surface-area silica particles. The second column contains either high-surface-area silica particles coated with silver ions or strong-cation-exchange material loaded with silver ions. Two switching valves are used to direct the different classes of components through the chromatographic system to the detector. In a forward flow mode, saturates (normal and branched alkanes, cyclic alkanes) pass through both columns to the detector, while the olefins are trapped on the silver-loaded column, and the aromatics and oxygenates are retained on the silica column. The latter two are subsequently eluted from the silica column to the detector in a back-flush mode. Finally, the olefins are back-flushed from the silver-coated column to the detector. A flame ionization detector (FID) is used for quantitation. Calibration is based on the area of the chromatographic signal for olefins, relative to standard reference materials, which contain a known mass % of total olefins as corrected for density.

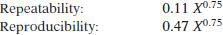

TEST PRECISION

Where X is the mean concentration between 1 and 25 mass %.

Since there is no material with an accepted reference value available, no statement regarding bias of this method can be made.