1. Direct method

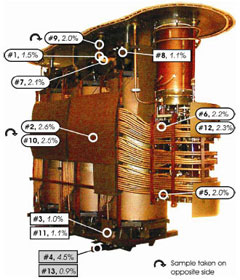

Take paper sample from transformer and measure moisture content using Karl Fisher titration.

Note:

(1) Only possible during repair or tear-down

(2) Moisture content in pressboard/paper samples is pending where the sample was located

(3) Averaging many results is necessary to get a "true" value

(4) Variations between different laboratories

Not practical as a standard diagnostic method.

2. Indirect methods

2.1 Moisture in oil

(1) Absolute values

A. Oil sampling under service conditions

B. Measurement of water content by Karl Fischer titration

C. Deriving moisture content in paper via equilibrium diagrams

Note:

The procedure is easy to perform and very common but affected by substantial potential errors:

A. Sampling and transportation of samples

B. Large variation in laboratory results

C. Diagrams only valid under equilibrium conditions (rarely happens during normal operation)

D. Standard diagrams does not cover aged oil and/or cellulose that may have different solubility

The method tend to overestimate moisture in solid insulation.

(2) Relative saturation (Moisture saturation measurements)

A. Measure relative water saturation ("ppm/solubility") in oil (%) instead of absolute moisture by weight (ppm)

B. More accurate than oil sampling method since no oil handling is involved

C. Moisture absorption capacity is less temperature dependent

D. Still requires equilibrium and charts are pending material

2.2 Power frequency tan delta/power factor measurements

(1) Measure tan delta/power factor at actual temperature

(2) Convert data to reference temperature (20℃)

(3) Compare with guidelines

Guidelines (examples):

"Tan delta/power factor < 0.5% @ 20C is OK" (IEEE 62-1995)

"Tan delta/power factor < 1% @ 20C may be OK for a service aged transformer"

(IEEE 62-1995)

"Expect tan delta/power factor < 0.3% for a dry transformer" (Doble)

Note:

The procedure is easy to perform and very common but is affected by errors and limitations

(1) Standard temperature correction tables are not accurate for the individual transformer

(2) Moisture in paper has a low influence on tan delta/power factor at typical measurement temperatures

(3) Not possible to tell if an increased tan delta value is caused by high moisture in paper or high oil conductivity/dissipation factor

2.3 Dielectric response measurements

(1) Return Voltage Measurement (RVM) - DC method

(2) Polarization-Depolarization Current measurements (PDC) - DC method

(3) Dielectric Frequency Response measurements (DFR/FDS) - AC method