EXPLANATION

Lubricating greases are used in almost all bearings used in any machinery. Lubricating greases are composed of about 90 % additized oil and soap or other thickening agent. There are over a dozen metallic elements present in grease, either blended as additives for performance enhancements or as thickeners, or in used grease present as contaminants and wear metals. Determination of their concentration can be an important aspect of grease manufacture. The metal content can also indicate the amount of thickeners in the grease.

This is the first industry standard available for simultaneous multi-element analysis of lubricating greases. The metals determined by this method include Al, Sb, Ba, Ca, Fe, Li, Mg, Mo, P, Si, Na, S, and Zn. It may also be possible to determine other elements such as Bi, B, Cd, Cr, Cu, Pb, Mn, K, Ti, etc., by this technique.

TEST SUMMARY

A weighed portion of the grease sample subjected to alternate means of sample dissolution which may include sulfated ashing in a muffle furnace or by closed vessel microwave digestion in acid. Ultimately, these diluted acid solutions are analyzed using ICP-AES. Aqueous calibration standards are used. The solutions are introduced to the ICP instrument by free aspiration or an optional peristaltic pump.

Interferences - Spectral interferences can usually avoided by judicious choice of analytical wavelengths. If the grease sample contains refractory additives such as Si or Mo, it is possible that some of these elements may remain undissolved in the residue, and may result in lower recoveries. If HF is used for dissolution of grease residues, elements such as silicon may be lost as SiF6. Residual HF can also attack the ICP sample introduction system. HF can be passivated by adding dilute boric acid to the acid solution. If the dry ashing in sample preparation step is used, elements such as sulfur will be volatilized during combustion.

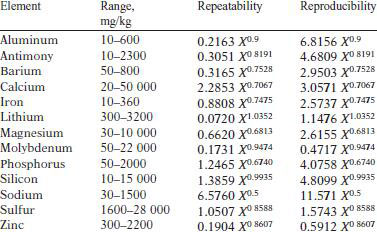

TEST PRECISION

NOTE: X = mean concentration in mg/kg.