TEST SUMMARY

This test method covers the determination of additive elements calcium, chlorine, copper, magnesium, phosphorus, silicon, and zinc in unused lubricating oils, additives, and additive packages. Matrix effects are handled with mathematical corrections. This test method uses regression software to determine calibration parameters, which can include interelement effect coefficients, usually referred to as alphas. Alphas can also be determined from theory using relevant software.

The X-ray spectrometer is initially calibrated for each element by determining the slope and intercept of the calibration curve by regressing concentration data and intensities measured on a set of physical standards. Theoretical alphas, or a combination of theoretical and empirical alphas can also be used. A sample is placed in the X-ray beam and the intensities of the appropriate fluorescence lines are measured. A similar measurement is made at an offset wavelength to obtain a background correction. Enhancement or absorption of the X-rays can occur, and these effects can be handled in the data reduction by implementation of alphas. Concentrations of the analytes are determined by comparison of net signals against calibration curves.

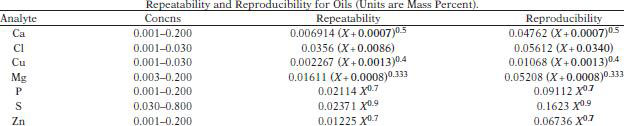

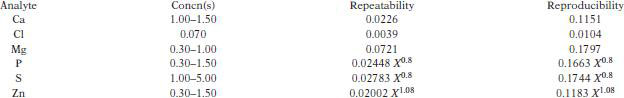

TEST PRECISION

See the following tables for precision estimates for lubricating oils and additives.

NOTE: X = concentration in mass %.

NOTE: X = concentration in mass %.

The bias was found to be not significant based on the analysis of synthetically prepared oils.