(Equivalent Test Methods: IP 377, ISO 10478, and DIN 51416)

EXPLANATION

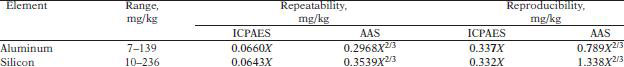

Catalyst fines in fuel oils can cause abnormal engine wear. These test methods provide a means of determining silicon and aluminum, the major constituents of the catalysts. The concentration range determined is between 5 and 150 mg/kg for aluminum and 10 to 250 mg/kg for silicon.

TEST SUMMARY

Two test methods are available, one using ICPAES, and the other using flame AAS. A sample is heated in a platinum dish, the combustible material is removed by burning, and the carbon finally removed by heating in a muffle furnace at a temperature of 550 +/- 25° C. The residue is fused with a lithium tetraborate/lithium fluoride flux. The fused mixture is digested in a solution of tartaric and hydrochloric acids, and diluted to volume with water. The aluminum and silicon in the resultant solution are measured with either atomic absorption spectrometry or inductively coupled plasma atomic emission spectrometry.

TEST PRECISION

Where X is the mean concentration in mg/kg.

The bias of this test method has not been determined.