(Equivalent Test Methods: IP 55, ISO 3841, and DIN 51570)

EXPLANATION

Melting point (cooling curve) is a test widely used by wax suppliers and consumers. It is particularly applied to petroleum waxes that are rather highly paraffinic or crystalline in nature. A plateau occurs with specimens containing appreciable amounts of hydrocarbons that crystallize at the same temperature, giving up heat of fusion, thus temporarily retarding the cooling rate. Generally, petroleum waxes with large amounts of nonnormal hydrocarbons or with amorphous solid forms will not show the plateau. This test method is unsuitable for the waxes of the petrolatum group, microcrystalline waxes, or blends of such waxes with paraffin wax or scale wax. Other methods used for petroleum waxes are Test Methods ASTM D127 and ASTM D938. However, results may differ depending on the test method used.

TEST SUMMARY

A molten wax specimen is placed in a test tube fitted with a thermometer and placed in an air bath, which in turn is surrounded by a water bath held at 16 to 28° C (60 to 80° F). As the molten wax cools, periodic readings of its temperature are taken. When solidification of the wax happens, the rate of temperature decreases, yielding a plateau in the cooling curve. The temperature at that point is recorded as the melting point (cooling curve) of the sample.

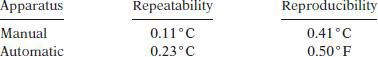

TEST PRECISION

This test method has no bias.