EXPLANATION

Wear due to excessive friction resulting in shortened life of engine components such as fuel pumps and fuel controls have sometimes been ascribed to lack of lubricity in an aviation fuel. The relationship of test results to aviation fuel system component distress due to wear has been demon-strated for some fuel/hardware combinations where boundary lubrication is a factor in the operation of the component. The wear scar generated in the ball-on-cylinder lubricity evaluator (BOCLE) test is sensitive to contamination of the fluids and test materials, the presence of oxygen and water in the atmosphere, and the temperature of the test. Lubricity measurements are also sensitive to trace materials acquired during sampling and storage. The BOCLE test may not directly reflect operating conditions of engine hardware. Some fuels that contain a high content of certain sulfur compounds may give anomalous test results.

TEST SUMMARY

The test fluid is placed in a test reservoir in which air is maintained at 10 % relative humidity. A nonrotating steel ball is held in a vertically mounted chuck and forced against an axially mounted steel ring with an applied load. The test cylinder is rotated at a fixed speed while being partially immersed in the fluid reservoir. The wear scar generated on the test ball is the measure of fluid lubricating properties.

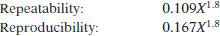

TEST PRECISION

Where X is the wear scar diameter in mm.

This test method has no bias.