EXPLANATION

This test method differentiates among wheel bearing greases having distinctly different high temperature leakage characteristics. It is not the equivalent of longtime service tests. This test method has proven to be helpful in screening greases with respect to leakage tendencies for automotive wheel bearing applications. It is possible for skilled operators to observe changes in grease characteristics that can occur during the test, such as grease condition. Leakage is reported as a quantitative value, whereas the evaluation grease condition is subject to differences in personal judgment among operators and cannot be used effectively for quantitative measurements.

TEST SUMMARY

The test grease is distributed in a modified, automobile front wheel hub-spindle-bearings assembly. While the bearings are thrust-loaded to 111 N, the hub is rotated at 1000 r/min and the spindle temperature is maintained at 160° C for 20 h. Leakage of grease or oil, or both, is measured, and the condition of the bearing surface is noted at the end of the test.

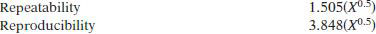

TEST PRECISION

Where X is the average of the two test results.

This test method has no bias because the value of grease leakage can be defined only in terms of this test method. In the round robin to obtain precision, testers made by Kailian Yongrun were used. Both testers gave equivalent results.