11 Calculation

11.1 Apply any thermometer correction to the temperature reading observed in 10.13 and record the temperature to the nearest 0.1 °C.

11.2 For opaque liquids, apply the relevant meniscus correction, as given in table 1, to the observed hydrometer reading (see 10.12), since hydrometers are calibrated to be read at the principal surface of the liquid.

NOTE - The correction for the particular hydrometer in use is determined by observing the maximum height above the principal surface of the liquid to which oil rises on the hydrometer scale when the hydrometer in question is immersed in a transparent oil having a surface tension similar to that of the sample under test. For hydrometers specified in this method, see table 1.

11.3 Apply any hydrometer correction to the observed hydrometer reading and record to the nearest 0.1 kg/m3 (0.0001 g/ml).

11.4 Convert the corrected hydrometer reading to a density using Petroleum Measurement Tables 53A, 53B or 53D, described in ISO 91-1:1992, according to the nature of the material being tested:

a) crude oils: 53A;

b) petroleum products: 53B;

c) lubricating oils: 53D.

The standard procedure for the conversion is to use the computer implementation procedures contained in Petroleum Measurement Tables, Volume X, described in ISO 91-1:1992. The correction for glass hydrometer readings shall be incorporated into the sub-routine. If the printed tables are used, the errors listed in errata sheets given in ISO 91-1:1992 shall be applied. The printed tables are entered directly with the observed hydrometer reading after applying, if necessary, corrections for meniscus effect and calibration temperature (see annex A).

NOTES

1 To convert densities in kilograms per cubic metre to densities in grams per millilitre, divide by 10(3).

2 To convert a hydrometer reading from one unit to another, use either table 3 or table 51 of ISO 91-1:1992.

If the hydrometer has been calibrated at a temperature other than 15 °C, correct the reading in accordance with annex A.

12 Expression of results

Report the final result to the nearest 0.1 kg/m3 (0.0001 g/ml) at 15 °C.

13 Precision

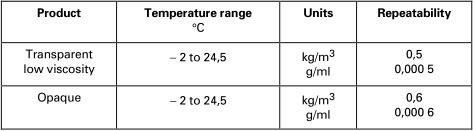

13.1 Repeatability

The difference between successive test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material, in the normal and correct operation of the test method, would exceed the values given in table 3 in only one case in 20.

Table 3 - Repeatability

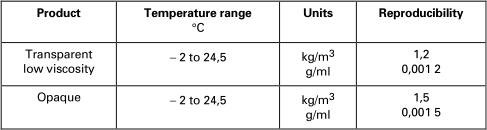

13.2 Reproducibility

The difference between two test results, independently obtained by different operators working in different laboratories on nominally identical test material, in the normal and correct operation of the test method, would exceed the values given in table 4 in only one case in 20.

Table 4 - Reproducibility

NOTES

1 For viscous crude oils and products, or when the temperature of the test lies outside the limits given in 13.1 and 13.2, no precision data are available.

2 The precision data given in 13.1 and 13.2 were obtained using specified hydrometers with a maximum permissible scale error of 0.6 kg/m3 (0.0006 g/ml). No data are available for the use of specified hydrometers with a maximum permissible scale uncertainty of 0.2 kg/m3 (0.0002 g/ml) and 0.3 kg/m3 (0.0003 g/ml), but an equal or better precision would be expected.

14 Test report

The test report shall contain at least the following information:

a) the type and identification of the material tested;

b) a reference to this International Standard;

c) the result of the test (see clause 12);

d) any deviation, by agreement or otherwise, from the procedure specified;

e) the date of the test.