5 Apparatus

5.1 Hydrometer cylinder, of clear glass, plastics material, or metal, with an inside diameter at least 25 mm greater than the outside diameter of the hydrometer (5.2) and a height such that the hydrometer floats in the test portion with at least 25 mm clearance between the bottom of the hydrometer and the bottom of the cylinder.

Plastics material used for the construction of hydrometer cylinders shall be resistant to discolouration or attack and shall not affect the properties of the material being tested. In addition, they shall not become opaque under prolonged exposure to light.

NOTE - For convenience in pouring, the hydrometer cylinder may have a lip on the rim.

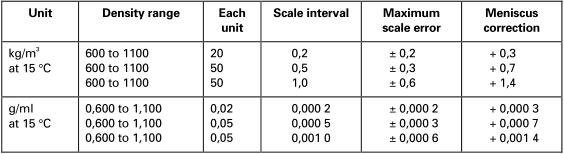

5.2 Hydrometers, of glass, graduated in units of density, conforming to ISO 649-1 and the requirements given in table 1. (See also annex A.)

Table 1 - Requirements for hydrometers

5.3 Constant temperature bath, if required, of dimensions such that it can accommodate the hydrometer cylinder with the test portion fully immersed below the surface of the bath liquid and a temperature control system capable of maintaining the bath at the test temperature +/- 0.25 °C, throughout the duration of the test.

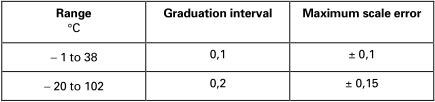

5.4 Thermometer, having a range, graduation intervals and maximum permitted scale error as shown in table 2.

Table 2 - Requirements for thermometers

NOTES

1 Thermometers IP 39C and IP 64C/ASTM 12C are suitable.

2 Resistance thermometers may be used, provided that the total uncertainty of the calibrated system is not greater than the uncertainty when using liquid-in-glass thermometers.

5.5 Glass or plastics stirring rod, optional, approximately 450 mm in length.

6 Sampling

Samples shall be taken in accordance with ISO 3170, ISO 3171, or an equivalent National Standard.

NOTE - When sampling volatile liquids using an automatic sampling technique, unless a sample receiver of variable volume is used to collect the sample and transport it to the laboratory, loss of light components may occur which will affect the accuracy of the density measurement.

7 Sample preparation

7.1 Sample mixing

The portion of the sample tested shall be as representative as possible of the bulk sample, and sample mixing may be necessary. However, precautions shall be taken to maintain the integrity of the sample during this operation.

The mixing of volatile crude oils and petroleum products containing sediments and/or water, or the heating of waxy volatile crude oils or petroleum products may result in the loss of light components. Guidance as to how to treat the different materials and to minimize such light component loss is given in 7.1.1 to 7.1.4.

7.1.1 Volatile crude oils and petroleum products having a RVP greater than 50 kPa Mix the sample wherever possible in the original container, and in a closed system in order to minimize the loss of light components.

NOTE - Mixing volatile samples in open containers will lead to loss of light components and will affect the value of the density obtained.

7.1.2 Waxy crude oils

If the crude oil has a pour point above 10 °C, or a cloud point or WAT (3.3) above 15 °C, warm the sample to 9 °C above its pour point, or 3 °C above its cloud point or WAT, prior to mixing. Mix the sample wherever possible in the original container, and in a closed system in order to minimize the loss of light components.

7.1.3 Waxy distillates

Warm the sample to 3 °C above its cloud point or WAT prior to mixing.

7.1.4 Residual fuel oils

Heat the sample to the test temperature prior to mixing (see 7.2.1 and note 2 in 7.2.1).

7.2 Test temperature

7.2.1 Bring the sample to the test temperature which shall be such that the sample is sufficiently fluid, but not so high as to cause loss of light components, nor so low as to result in the presence of wax in the test sample.

NOTES

1 The density determined by the hydrometer method is most accurate at or near the reference temperature of 15 °C.

2 The hydrometer reading is obtained at a temperature appropriate to the physio-chemical characteristics of the material being tested. This temperature is preferably close to the reference temperature of 15 °C or, when the density is used in conjunction with bulk oil measurements, close to +/- 3 °C, or at the bulk oil temperature, to minimize errors due to volume correction.

7.2.2 For crude oil, bring the sample to 15 °C, or 9 °C above its pour point, or 3 °C above its cloud point or wax appearance temperature, whichever is the higher.

NOTE - For crude oil, an indication of the wax appearance temperature can be found using IP 389 (see [4] in annex B) with the modification of using 50 µl +/- 0,5 µl of sample. The precision for determining WAT of crude oils using IP 389 has not been determined.

8 Verification of apparatus

8.1 Hydrometers shall be regularly verified by comparison with a reference hydrometer traceable to a National Standard or a traceable density certified reference material (CRM), and where necessary recalibrated at least every five years.

8.2 Thermometers shall be regularly verified by comparison with a reference thermometer traceable to a National Standard.

9 Preparation of apparatus

9.1 Check that the hydrometer scale is correctly located within the hydrometer stem by reference to the datum mark. If the scale has moved, reject the hydrometer.

9.2 Bring the hydrometer cylinder and hydrometer to approximately the sample temperature (see 7.2.1 and note 2 in 7.2.1).