6 Instrument set-up

6.1 Gas chromatograph

6.1.1 General

Differences between gas chromatographs and detectors from different manufacturers make it impractical to provide detailed operating conditions. Consult the manufacturer's instructions for operating the instrument to facilitate separation and detection of DBDS.

6.1.2 Carrier gas

Helium or other suitable gas with purity higher than 99.999 % is recommended as the carrier gas.

6.1.3 Injector

A split/splitless injector is used to introduce a known amount of sample into the gas chromatographic column. The split/splitless injector parameters should be chosen taking into account the capability of the column and the dilution of the sample.

For samples that have been diluted 20 fold, the split mode is appropriate.

The injector temperature should be maintained at 275 °C to avoid condensation of the oil. A borosilicate glass liner with glass-wool is recommended to increase the vaporization rate of the injected sample.

6.1.4 Separation parameters

Capillary columns, 30 m to 60 m, with 0.25 mm internal diameter and 0.32 µm 5 % phenyl 95 % methyl polysiloxane stationary phase thickness, have been found to be suitable for chromatographic separation of DBDS. Good chromatographic separation can also be achieved with columns with other suitable stationary phases (e.g. methyl polysiloxane). When using columns with other stationary phases, chromatographic separation of organo-sulfur compounds should be checked to ensure adequacy of separation prior to the use of columns for DBDS analysis.

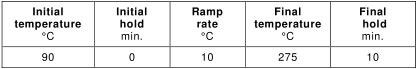

Column oven temperature programming parameters given in Table 1 have been found to give satisfactory separation; however, other parameters may be used with other columns.

Table 1 - Column oven temperature programming parameters

The temperature ramp may be adjusted to optimize separation and elution time.

A carrier gas flow rate between 0.8 ml/min to 1.5 ml/min is suitable.

6.1.5 ECD detection

Set the ECD detector to a temperature of 280 °C to 340 °C. Nitrogen or other suitable gas is used as the make-up gas. Follow the manufacturer's recommendation for operation of the ECD.

6.1.6 AED detection

Set the AED detector for detecting the sulfur emission line at 181 nm (or other suitable wavelength). Hydrogen and oxygen are normally used as the reagent gases in the discharge tube of the AED emission source.

An automatic correction of background is recommended, due to the interferences of carbon at 179 nm. Follow the manufacturer's recommendation for operation of the AED.

6.1.7 MS detection

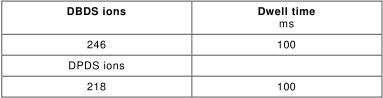

Operate the MS with an EI source in positive ion mode and set the electron energy at 70 eV.GC-MS interphase and source temperature should to set at 270 °C and 200 °C, respectively. Set the MS in SIM mode for detection and quantification of selected DBDS and DPDS ions given in Table 2. Follow the manufacturer's instruction for setting up the instrument.

Table 2 - Mass spectrometer parameters

6.1.8 MS/MS detection

Operate the tandem MS with an electron ionization (EI) source in positive ion mode, set electron energy at 70 eV. Detection is carried out with a triple quadrupole mass spectrometer operated with an EI source in the positive ion mode. GC-MS interphase and source temperatures should be set at 270 °C and 200 °C, respectively. In a triple quadrupole system the first quadrupole (Q1 ) mass filter shall be set to transmit ions with m/z 218 and m/z 246 for DPDS and DBDS. Ion energy should be set at 15 eV. The second quadrupole (Q2) shall be operated as the collision chamber in which collisions of selected precursor ion with argon atoms (Ar) lead to fragment ion through collision induced dissociation (CID). The collision gas pressure shall be set at 0,2 mtorr. The third quadrupole (Q3) shall be set to transmit product ion with m/z 91 and m/z 109 [3]. Follow manufacturer's instructions for setting up of the instrument.

6.2 Calibration

6.2.1 General

The response of DBDS is compared with the response of a known amount of DPDS (IS).

6.2.2 Calibration procedure

Prepare the calibration standard solutions by introducing known volumes of the stock solution (see 5.7.1) in DBDS free mineral oil. Weigh out 0.25 g aliquots of the fortified oil samples to the nearest 0.001 g and dilute with 5ml of isooctane or other suitable solvent. Add a known amount of the IS solution (see 5.7.2) to the calibration standard.

Calibration standard solutions should be prepared fresh each month. If the standard solutions are kept for longer periods, these should be compared with fresh solutions. Calibration standards should cover the 5 mg kg(-1) to 600 mg kg(-1) concentration range, an IS concentration of 50 mg kg(-1) has been found to be satisfactory.

6.2.3 Response factor determination (ECD and AED)

Add a known amount of IS solution (see 5.7.2) by weight or using a calibrated syringe (with 50 mg kg(-1) IS).

Analyse the fortified oil samples following the same procedure used for the samples. Run the analysis in triplicate.

Calculate the response factor (k) as:

k = [AIS x mDBDS] / [mIS x ADBDS]

where

AIS is the area of the DPDS or other suitable IS peak;

ADBDS is the area of the DBDS peak;

mDBDS is the mass of DBDS added to the oil in mg;

mIS is the mass of DPDS or other suitable IS added to the oil in mg.

6.2.4 Response factor determination (MS)

Add a known amount of IS solution (see 5.7.2) by weight or using a calibrated syringe (with 50 mg kg(-1) IS).

Analyse the fortified oil samples following the same procedure used for the samples. Run the analysis in triplicate.

Calculate the constant RF (k) as:

k = [AIS x mDBDS] / [mIS x ADBDS]

where

AIS is the area of the molecular ion peak m/z 218 of the DPDS (IS); a suitable ion shall be monitored in case a different IS is used;

ADBDS is the area of the molecular ion peak m/z 246 of the DBDS;

mDBDS is the known mass of DBDS added to the oil in mg;

mIS is the known mass of DPDS or other suitable IS added to the oil in mg.

6.2.5 Response factor determination (MS/MS)

Add a known amount of IS solution (see 5.7.2) by weight or using a calibrated syringe (with 50 mg kg(-1) IS).

Analyse the fortified oil samples following the same procedure used for samples. Run the analysis in triplicate.

Calculate the constant RF (k) as:

k = [AIS x mDBDS]/[mIS x ADBDS]

where

AIS is the area of the fragment ion peak m/z 109 resulting from collision-induced dissociation (CID) of molecular ion m/z 218 of the DPDS; another suitable ion shall be selected when a different IS is used;

ADBDS is the area of the fragment ion peak m/z 91 resulting from CID of molecular ion m/z 246 of the DBDS;

mDBDS is the known mass of DBDS added to the oil in mg;

mIS is the known mass of DPDS or other suitable IS added to the oil in mg.

6.3 Analysis

6.3.1 Sample pre-treatment

Weigh out a 0.25 g aliquot of homogenized oil sample into a glass container to the nearest 0.001 g. Record the weight of sample as WOIL.

Dilute to 5 ml with isooctane or other suitable solvent.

Add (by weight or volume) a known amount of DPDS; the recommended amount is 50 µg.

Mix the solution obtained by shaking it briefly by hand, and take an aliquot for the analysis.

6.3.2 Sample injection

Inject 1 µl of sample solution into the gas chromatographic system by means of a micro syringe. The use of an automated sampler is preferred.

If a split technique is used, set the appropriate split ratio and the injected volume.

6.3.3 Chromatographic run

Run the established temperature ramp, acquire and store the detector (ECD, AED or other suitable detector) signal with suitable chromatographic data system.

6.3.4 Peak integration

The data systems are equipped with peak integration capability. Verify the proper integration and, in case of error, make manual adjustment if and when required.

Record the area of DBDS peak as ADBDS and the area of DPDS peak as AIS; use these for calculating DBDS concentration.

6.4 Calculations

6.4.1 ECD and AED

Calculate the DBDS concentration in oil with Equation (4):

mg kg(-1) [µg g(-1)] DBDS = [k x mIS x ADBDS]/[AIS x WOIL]

where

AIS is the area of the peak of the DPDS;

ADBDS is the area of the peak of the DBDS (if detected);

mIS is the mass of DPDS added into the sample oil;

WOIL is the amount of oil weighted for the analysis.

6.4.2 Mass spectrometer (MS)

Calculate the result as:

mg kg(-1) [µg g(-1)] DBDS = [k x mIS x ADBDS (m/z 246)]/[AIS (m/z 218) x WOIL]

where

AIS is the area of the extracted molecular ion peak m/z 218 of the DPDS, when a different IS is used, another suitable ion peak shall be monitored;

ADBDS is the area of the extracted molecular ion peak m/z 246 of the DBDS;

mIS is the mass, in mg, of DPDS or other suitable IS added to the sample oil;

WOIL is the weight of the oil sample used for the analysis.

6.4.3 MS/MS

Calculate the result as:

mg kg(-1) [µg g(-1)] DBDS = [k x mIS x ADBDS (m/z 91)]/[AIS(DPDS m/z 109) x WOIL]

where

AIS is the area of the fragment ion peak m/z 109 resulting from CID of molecular ion m/z 218 of the DPDS; another suitable ion shall be selected when a different IS is used;

ADBDS is the area of the extracted ion peak of the DBDS at m/z 91 (if detected);

mIS is the mass of DPDS added into the sample oil (in µg);

WOIL is the amount of oil weighted for the analysis (in g).

6.5 Results

Report DBDS concentrations in mg kg(-1) to two significant figures.

7 Precision data

7.1 Detection limit

Detection limit for the procedure outlined above is expected to be ≤ 5 mg kg(-1). Each laboratory should determine its own detection limit.

7.2 Repeatability

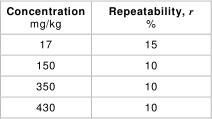

Duplicate determinations carried out by one laboratory should be considered suspect at the 95 % confidence level if they differ by more than the value reported in Table 3 (expressed as a percentage of the average value).

Table 3 - Repeatability limit

7.3 Reproducibility

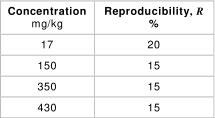

Duplicate determinations carried out by different laboratories should be considered suspect at the 95 % confidence level if they differ by more than the value reported in Table 4 (expressed in percentage of the average value).

Table 4 - Reproducibility limit

8 Report

The test report shall contain at least the following information:

• the name of testing laboratory;

• the type and identification of the product tested;

• a reference to this standard, IEC 62697-1.

• the result of the test (see 6.5).

• the procedure used, including the type of detector.

• any deviation, by agreement or otherwise, from the procedure specified.

• the date of the test.