3 Methods for the determination of anti-oxidant additives

3.1 Determination of phenolic and amine-based antioxidants by infrared (IR) spectrophotometry - Method A

3.1.1 Introductory remark

This method determines the amount of 2,6-di-tert-butyl-para-cresol (DBPC) in unused and used mineral oils by measurement of the infrared absorption at the (O-H) stretching frequency of hindered phenols. It can also be used to determine the amount of 2,6-di-tert-butyl-phenol (DBP), but does not discriminate between them.

The previous test method in the first edition of IEC 60666 described a procedure for the determination of specific antioxidants using IR techniques. This test method was satisfactory with new oils, where no oxidation by-products interfere with the antioxidant. However, this method was less satisfactory for used oils because oxidation by-products may modify the IR baseline, making the detection and quantification of the antioxidants difficult. To overcome this problem, a procedure for preparing a reference oil to be used as a baseline was described. Unfortunately, this procedure was difficult to perform, was time-consuming and did not ensure that the new baseline matched adequately that of the oil to be analysed, because the content of some components of the baseline oil and the analysed oil could be quite different.

This new method describes a procedure for preparing reference, antioxidant-free oils by solid phase extraction (SPE) using silica gel.

3.1.2 Equipment, materials and solvents

The following materials and reagents are used:

- FT-IR or double-beam IR spectrometer having matched 1 mm sodium chloride cells (other materials are accepted provided they do not absorb IR radiation in the range 3000 cm(-1) to 3800 cm(-1);

- 5 ml or 10 ml round-bottom flasks;

- 5 ml or 10 ml beakers;

- rotary evaporator;

- silica gel cartridges (1 g or 2 g size is satisfactory);

- n-pentane, analytical grade.

3.1.3 Sample preparation

Into a beaker pour 1 g of the oil to be analysed for antioxidants, add 2 ml of analytical grade n-pentane and mix thoroughly.

Filter the solution through a silica gel cartridge and recover the eluate in a round-bottom flask. Evaporate the n-pentane in the rotary evaporator.

Take a portion large enough to completely fill one IR cell of the oil that remains in the flask, fill one IR cell and put it on the reference beam of the spectrometer.

Fill a second IR cell with the oil to be analysed, which has not been submitted to the filtration process, and insert it on the analytical beam of the spectrometer.

Record the IR spectrum as described in 3.1.5.

3.1.4 Calibration

Prepare standard calibration solutions by dissolving weighed amounts of DBP or DBPC inhibitor in weighed amounts of antioxidant-free oil, prepared if necessary from the oil sample under test using the procedure in 3.1.3 (larger cartridges and amounts of oil will be necessary).

The maximum life of the standard solution shall be six months.

NOTE The calibration solutions may be prepared using an unused, inhibitor-free oil, provided the base oil is known to be the same as that under test. The oil should be tested by this procedure to ensure that no inhibitor is detectable. This alternative should not be used where the oil under test is heavily aged.

Prepare at least five calibration solutions, covering the range 0.02 % to 0.50 % inhibitor by mass.

Intermediate standards may be prepared if necessary when the approximate concentration of inhibitor in the sample is known.

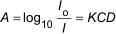

The absorbance (at 3650 cm(-1) for DBPC) of the calibration solutions is recorded as described in 3.1.5 and a calibration curve of absorbance against per cent inhibitor content produced. The calibration should be a straight line passing through the origin, according to the Beer-Lambert law of absorption:

where

A is the absorbance;

Io is the intensity of incident radiation;

I is the intensity of transmitted radiation;

K is the extinction coefficient (constant for (O-H) of DBPC);

C is the concentration of DBPC in percentage by mass;

D is the cell path-length.

Since K and D are constant for this determination, A is directly proportional to C.

3.1.5 Analysis

1. FT-IR instrument

Check the equipment. The quality tests should be performed according to the manufacturer's recommendations.

2. Double-beam IR spectrophotometer

Prepare two matched liquid cells with path-lengths of 1 mm and sodium chloride windows. Fill both cells with the base oil and, with one cell in the sample beam and the other in the reference beam of the spectrometer and check that the IR spectrum between 3800 cm(-1) and 3400 cm(-1) is a straight line. Record the percentage transmittance (95 % - 100 %).

Exchange the cells, i.e. transfer the cell in the sample beam to the reference beam and the cell in the reference beam to the sample beam. Repeat the spectrum acquisition and again ensure a straight line of approximately 95 % to 100 % transmittance is obtained.

If the above conditions are not obtained, clean and polish or reject windows that have an absorbance in this region, and repeat the process until a matched pair of cells is obtained. These are then used for all the determinations.

Test solutions

1. FT-IR instrument

Fill the cell with the oil to be analysed and record the IR spectrum (A) at the appropriate wavelength. Repeat using the inhibitor-free reference oil and subtract this result from spectrum A to produce a spectrum with a linear baseline.

2. Double-beam IR spectrophotometer.

Take a portion of the inhibitor-free reference oil in the flask, completely fill an IR cell and place it in the path of the reference beam of the spectrometer. Completely fill a second IR cell with the oil to be analysed and place it in the analytical beam of the spectrometer. Record the IR spectrum at the appropriate wavelength (in the range 3500 cm(-1) to 3700 cm(-1) for DBPC).

3.1.6 Calculation

Measurement of absorbance

1. FT-IR instrument

Record the absorbance at the position of maximum peak height for the sample and for the inhibitor-free reference oil.

Subtract the reference oil spectrum from the sample oil spectrum and quantify the result by reference to calibration curves.

2. Double-beam IR spectrophotometer (see Figure A.1)

Draw a base line as nearly as possible between 3610 cm(-1) and 3680 cm(-1) and record the percentage transmittance (Io) at which the base line crosses the 3650 cm(1) line.

Record the percentage transmittance at the tip of the peak at 3650 cm(-1) (I), then:

The percentage DBPC equivalent to A3650 is read from the calibration graph.

Alternatively, automatic determination by the spectrometer may be used.

3.1.7 Precision

The repeatability and reproducibility limits were established in accordance with the ISO 5725 series.

3.1.8 Repeatability

The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the values shown below by only 1 case in 20:

- unused and used oils - 15 %, which can be calculated as (x1 + x2)/2 x 0.15, where x1 and x2 are the results of the two replicates.

NOTE The repeatability values for oils only apply where the result is above 0.05 % DBPC in oil.

3.1.9 Reproducibility

The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the values shown below by only 1 case in 20:

- unused oils: for DBPC concentrations ≤ 0.1 %, the reproducibility is 0,02 % - absolute value;

- unused oils: for DBPC concentrations > 0.1 %, the reproducibility is 45 %, which can be calculated as (x1 + x2)/2 x 0.45, where x1 and x2 are the results of the two replicates;

- used oils - 45 %, which can be calculated as (x1 + x2)/2 x 0.45, where x1 and x2 are the results of the two replicates.

NOTE The reproducibility values for used oils only apply where the result is above 0.05 % DBPC in oil.

3.1.1 0 Report

Report the concentration of phenolic and amine-based antioxidants in % to the nearest 0.01 %.

3.2 Determination of 2,6-di-tert-butyl-para-cresol by IR spectrophotometry - Method B

For routine analysis of oils in service, a procedure, modifying 3.1 by the following changes, may be used.

3.2.1 Calibration

Prepare one liquid cell with a path length of 0.2 mm and equipped with sodium chloride windows.

Fill the cell with a mineral transformer oil without inhibitor (0 % inhibitor calibration solution) and measure the IR spectrum.

Prepare at least 3 calibration solutions by adding DBPC inhibitor to achieve concentrations between 0.1 % and 0.4 %.

Measure the IR spectrum of each calibration solution.

Measure the heights of the inhibitor characteristic peaks at approximately 3650 cm(-1) (see Figure A.2).

Construct the calibration line: height of the peak as a percentage of transmission - concentration of DBPC as mass per cent in oil.

3.2.2 Sample test - New or used oil

Fill and drain the calibrated cell with the test oil 3 times.

Fill the cell and measure the IR spectrum.

Measure the height of the inhibitor characteristic peak as a percentage of transmission by visual examination, in the same way as during the calibration procedure (see Figure A.2).

From the peak height, read the mass per cent of inhibitor in the oil sample under test using the calibration line.

3.2.3 Precision

The repeatability and reproducibility limits for method B have been established to be the same as for Method A.

3.2.4 Repeatability

The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, under normal and correct operation of the test method, exceed the values shown below by only 1 case in 20:

- unused and used oils - 15 %.

NOTE The repeatability values for oils only apply where the result is above 0,05 % DBPC in oil.

3.2.5 Reproducibility

The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the values shown below by only 1 case in 20:

- unused oils: for DBPC concentrations ≤ 0.1 %, the reproducibility is 0.02 % - absolute value;

- unused oils: for DBPC concentrations > 0.1 %, the reproducibility is 45 %;

- used oils - 45 %.

NOTE The reproducibility values for used oils only apply where the result is above 0.05 % DBPC in oil.

3.2.6 Report

Report the concentration of 2,6-di-tert-butyl-para-cresol (DBPC) in % to the nearest 0.01 %.

3.3 Determination of 2,6-di-tert-butyl-para-cresol (DBPC) by high performance liquid chromatography (HPLC)

3.3.1 Introductory remark

This method determines the amount of 2,6-di-tert-butyl-para-cresol (DBPC) in unused and used mineral oils by using high-performance liquid chromatography after sample preparation using solid phase extraction technique.

3.3.2 Materials and equipment

The following materials and equipment are used:

- HPLC with a UV or a diode array UV detector;

- column - an example of column found satisfactory is C18, 3.9 mm x 300 mm with 5 μm coating thickness;

- pre-column - C18, 5 μm;

- cartridges - 0.6 g to 1 g of silica;

- syringe filter - PTFE, maximum pore-size 0.5 μm (optional).

3.3.3 Reagents and solvents

Reagents shall comprise:

- methanol, HPLC grade;

- water, HPLC grade;

- n-pentane, HPLC grade.

3.3.4 Solid-liquid extraction

Weigh between 0.25 g and 0.5 g of oil sample to an accuracy of 0.01 g and dissolve it in 2.5 ml of n-pentane.

Rinse a new silica cartridge with 3 ml of n-pentane and discard the eluate. While the silica is still wet, immediately pass the sample solution through the cartridge under a slight vacuum at a maximum flow of 3 ml/min. Discard eluate.

Dry the cartridge by suction maintaining the vacuum for at least 10 min.

Stop the vacuum and elute the absorbed material with the same eluent to be used in the chromatographic analysis.

Collect the first 5 ml in a 5 ml volumetric flask.

It may be advantageous to filter this solution through a syringe filter when transferring it to a vial.

Transfer the eluate to a suitable vial for analysis by HPLC.

3.3.5 Analysis of the extract

The following conditions have been used:

Mobile phase: Isocratic conditions

Eluent: Levels between 100 % methanol and methanol containing up to 40 % of water (volume/volume) have been used.

Injection volume: 10 μl to 20 μl

Flow rate: 1 ml/min

Temperature: Isothermal at a temperature between 30 °C and 40 °C

Peak detection: About 276 nm to 278 nm with a retention time from about 3 min to 10 min depending on elution conditions.

See Figure A.3 for an example of the chromatogram.

3.3.6 Calculation

Peak areas or peak heights of the sample are compared with calibration standards prepared as in 3.1.4.

Plot a calibration curve of peak heights or peak areas against per cent inhibitor content. Read on the calibration curve the percentage of DBPC in the sample.

3.3.7 Precision

The repeatability and reproducibility limits were established in accordance with the ISO 5725 series.

3.3.8 Repeatability

The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, under normal and correct operation of the test method, exceed the values shown below by only 1 case in 20:

- unused and used oils - 15 %.

NOTE The repeatability values for oils only apply where the result is above 0.05 % DBPC in oil.

3.3.9 Reproducibility

The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, under normal and correct operation of the test method, exceed the values shown below by only 1 case in 20:

- unused oils: for DBPC concentrations ≤ 0,1 %, the reproducibility is 0.02 % - absolute value;

- unused oils: for DBPC concentrations > 0.1 %, the reproducibility is 45 %;

- used oils - 45 %.

NOTE The reproducibility values for used oils only apply where the result is above 0.05 % DBPC in oil.

3.3.10 Report

Report the concentration of 2,6-di-tert-butyl-para-cresol (DBPC) in % to the nearest 0,01 %.

3.4 Determination of phenolic inhibitors by gas chromatography - Mass spectrometry (GC-MS)

3.4.1 Summary of method

Solvent containing an internal standard (the dimethyl ester of phthalic acid) is added to the oil and to suitable calibration standards containing known amounts of 2,6-di-tert-butyl-phenol (DBP) and of 2,6-di-tert-butyl-para-cresol (DBPC). Samples and standards are injected on the GC (split injection) using mass spectrometric detection. Ion chromatograms of m/z = 191, 205 and 163 are used for the quantitation of DBP, DBPC and the internal standard, respectively. This method is applicable to all mineral oils, including such used oils where the IR spectrophotometric methods may suffer from interferences. Because of the high sensitivity of this method it can also be used to ascertain the absence of inhibitor in uninhibited oils.

3.4.2 Example of instrument parameters

Split injection: 1 μl injected, with a split ratio of 200:1 , at 275 °C

Carrier gas: Helium

Column head pressure: Constant flow mode, 1.2 ml/min

Column: 5 % phenyl- 95 % dimethyl-polysiloxane, 30 m, 0.25 mm, 0.25 μm or equivalent

GC temperature program: Start at 120 °C, hold for 1 min, increase 10 ºC/min until DBPC has eluted, then increase at 50 °C/min to 300 °C. Hold at 300 °C until the baseline is restored.

MS settings: EI+, 70 eV, trap temperature 1 50 °C, manifold temperature 80 °C, scan from m/z = 50 to 500, 3 scans per second to establish retention times and identities (3.4.7). Start scanning at 3 min, stop scanning at 7 min or later.

3.4.3 GC accessories

Liner: Split injection liner

Syringe: 5 μl or 10 μl

Washing solvent: Toluene

3.4.4 Calibration standard solutions

Weigh about 0.28 g of DBPC and/or DBP into a 10 ml vial and record the weight to +/- 0.001 g. Add about 8 g mineral oil complying with IEC 60296 containing no inhibitor and record the weight to +/- 0.01 g. Mix and stir with magnet until DBPC and DBP are dissolved, heating slightly if required. Prepare a series of calibration standard solutions containing 0.02 %, 0.04 %, 0.1 %, 0.2 % and 0.4 % by weight of the calibration standard solution above, using the same oil and mixing the solutions thoroughly.

The standards may be stored in darkness and cool conditions for maximum of 6 months.

3.4.5 Internal standard solutions

Solution 1: Weigh about 1.0 g dimethylphthalate into a 100 ml volumetric flask and record the weight to +/- 0.001 g.

Fill with toluene to 100 ml, record the weight and mix thoroughly.

Solution 2: Transfer 1000 μl of internal standard solution 1 into a 100 ml volumetric flask, fill up with toluene to 100 ml and mix thoroughly.

Do not store solution 2; it must be prepared for each set of analyses.

3.4.6 Preparation of samples and calibration standards

Add 100 μl of the sample(s) and of each of the series of calibration standard solutions into separate vials, then add 1000 μl of internal standard solution 2 and mix well. Analyse the sample(s) and the calibration standard solutions.

3.4.7 Analytical procedure

Set up and tune the MS according to the manufacturer's instructions.

Carry out a full scan for determination of the retention time and identification according to target ions of DBPC, DBP and dimethylphthalate and a SIM method (selective ion monitoring) for calibration and analysis.

NOTE For many mass spectrometers used as detectors, the ion chromatograms for quantitation can be extracted from chromatographic runs with full MS scans and with sufficient signal-to-noise ratio. In such cases, it is not necessary to run the MS in SIM mode. However, SIM might still be preferable in order to save on data storage capacity.

3.4.8 Calculation of results

Integrate and note the area for the target ions on DBPC, DBP and dimethylphthalate and calculate the RFx for each level of calibration standard:

RFx = [AIS/MIS]/[AC/MC]

where

AIS is the area of the internal standard;

MIS is the mass of the internal standard;

AC is the area of the compound;

MC is the mass of the compound.

The RFx from calibration, internal standard areas and sample areas are used for calculation of the inhibitor content. Use of a spreadsheet program is recommended.

CS = [AS/RFx]/[MIS/AIS] x MS

where

CS is the content of the sample;

AS is the area of the sample;

RFx is the reference factor from calibration;

MIS is the mass of the internal standard;

AIS is the area of the internal standard;

MS is the mass of the sample.

NOTE The method could be modified to include other sufficiently volatile phenolic inhibitors and also amine inhibitors. Some diphenylamines have been used in the past in transformer oils and may possibly still be used by some producers. However, BTA may decompose at the temperatures used in this method.

3.4.9 Precision

This method is capable of detecting anti-oxidants at trace levels or confirmation of absence of these compounds and, while only a limited number of laboratories were involved in evaluation, the precision is dependent principally on the dilution stage which can be easily evaluated by each laboratory.

3.4.10 Report

Report the concentration of 2,6-di-tert-butyl-para-cresol (DBPC) in % to the nearest 0.01 %.