IEC 60480 GUIDELINES FOR THE CHECKING AND TREATMENT OF SULFUR HEXAFLUORIDE (SF6) TAKEN FROM ELECTRICAL EQUIPMENT AND SPECIFICATION FOR ITS RE-USE

9 Analytical methods for SF6 and their significance

9.1 General

The methods for analysis of SF6 shall be used on gas samples. Details of the procedures for obtaining a sample and of the analytical methods are provided in Annex B.

9.2 On-site analysis

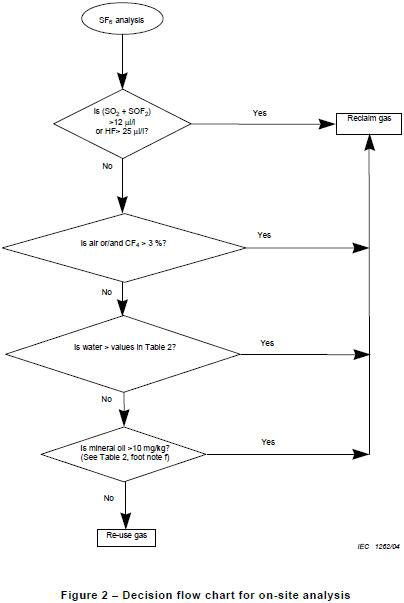

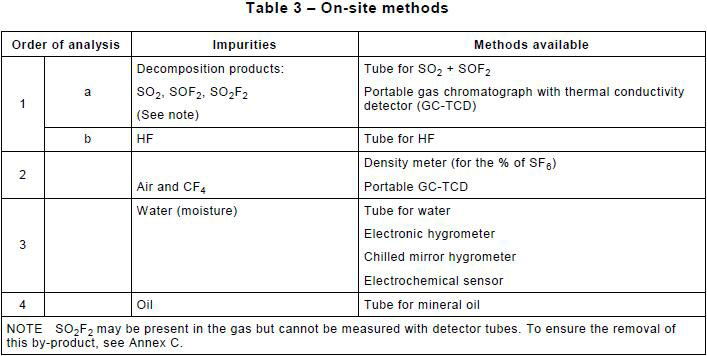

These methods are intended to be quick and simple for screening the gas. The order of analysis has been set to determine, as quickly as possible, if the gas is re-usable or reclaimable on-site (Figure 2).

If on-site analysis systems are available, the specification requires the use of possible amount of SF6, to avoid any release of SF6 to the atmosphere, and to health and safety of personnel. The order of the gas screening analysis and available analytical methods are shown respectively in Figure 2, Table 3 and Annex B.

For all on-site analysis, the operator shall follow the manufacturer's instructions concerning the accuracy of analytical equipment.

The analysis for SO2, SOF2 and HF are required first for two reasons: firstly for safety, to allow personnel to assess the risk involved in handling used SF6, and secondly to protect the analytical equipment against corrosion.

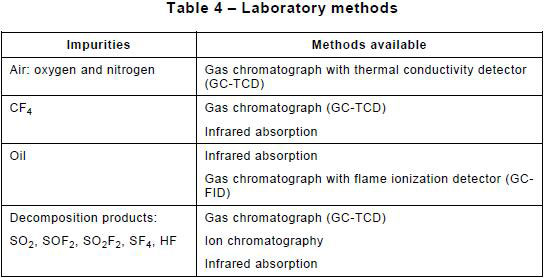

9.3 Laboratory analysis

If no equipment is available on-site, the following recommended techniques shall be used. Laboratory methods are intended to provide a quantitative assessment of the impurities in a gas sample.

Water is the only contaminant that cannot be determined accurately from a sampling cylinder. The water content of a sample in a cylinder taken from a reservoir is not representative of the water content in the reservoir because water adsorbs on all surfaces. Therefore, the water analysis should always be carried out directly on the reservoir on-site. There is no recommended order of analysis.