Although it is important to test the oil in transformers, it is more important to know how to interpret the data from the results. No one test can be used independently to determine the oil condition. Rather, all of the results should be reviewed simultaneously to give a full understanding about what is occurring in both the oil and the transformer. This will allow you to review the options and make a decision as to how to treat the oil.

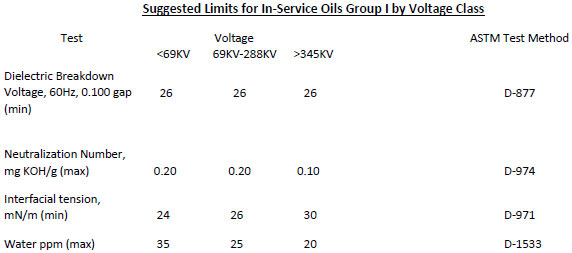

The IEEE Guide for reclamation of Insulating Oil and Criteria for Its Use (IEE Std 637-1985) has four group classifications for oil evaluation.

Group I: Oils that are in satisfactory condition for continued use.

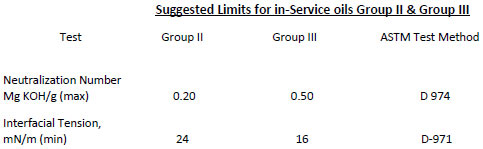

Group II: Oils that required only reconditioning for further service.

Group III: Oil in poor condition. Such oil should be reclaimed or diposed of depending upon economic considerations.

Group IV: Oil in such poor condition that it is technically advisable to dispose of it.

For oil that does not meet the recommended thresholds above, there are two options. One, the oil can be utilized in a lower voltage application, assuming it was utilized above a 69KV application. Two, the oil can be reconditioned or reclaimed to meet the Group I classification. Listed below are the thresholds for oil treatment.

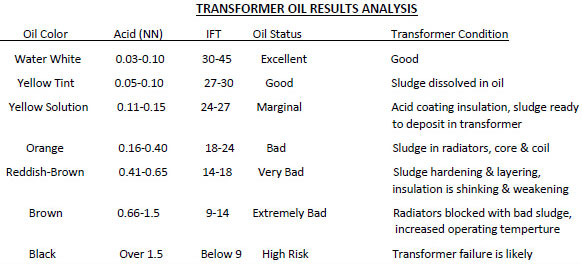

In terms of what is actually occurring in the transformer, listed below is a sample table that provides a general summary of what's happening in the transformer based on the neutralization number and the interfacial tension value.

Although the acid test determines conditions under which sludge may form, it does not necessarily indicate that sludging condition exist. The IFT test is a good indicator of the sludging characteristics of transformer oil because it correlates to the concentration of polar molecules in suspension and in the solution in the oil. Thus, the IFT test serves as an early warning to the beginning stages of deterioration.

It is Important to not just consider these two test as indicators as to whether or not oil treatment is necessary. Other oil quality results should be reviewed as well as dissolved gas analysis (DGA) results should also be considered.

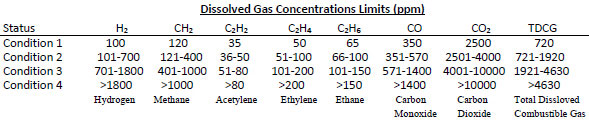

Dissolved Gas Analysis

Disolved gas analysis (DGA) and the information it can provide are particulary important in analyzing the health of the transformer and determining whether oil treatment is necessary. The rate of insulation decomposition will increase significantly in the presence of faults. By drawing a sample and having the gas composition analyzed, it's possible to distinguish between different fault types.

Although transformer oil testing is important, the results will be of no use if you don't know how to interpret them. If the oil doesn't meet the recommended level base on the IEEE Guide for Reclamation of Insulating Oil, then it should be reconditioned, reclaimed or disposed of based on the test results.

Condition 1 - TDCG below this level indicates the transformer is operating satisfactorily

Condition 2 - TDCG within this range indicatesgreater than normal combustible levels & should prompt additional investigation. (any gas exceeding specified levels)

Condition 3 - TDCG within this range indicates high level of decomposition (additional investigation required)

Condition 4 - TDCG within this range indicates excessive decomposition. Continued operation could result in failure of the transformer