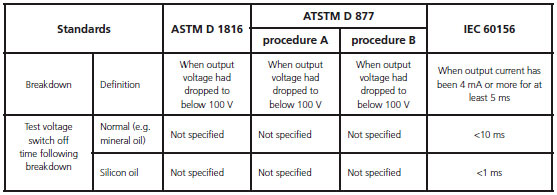

Efficient breakdown detection is very important as it determines the ability of the instrument to correctly register the breakdown voltage of the oil, and also to limit the amount of energy dissipated in the arc in the oil. For these reasons, the oil testing standards specify the precise conditions that must be met to trigger the instrument's breakdown detection system. There are, however, differences between the standards, as shown in the table below:

Modern test instruments detect breakdowns directly on the instrument output, which improves detection accuracy. Very few instruments are capable of breakdown detection that meets both IEC and ASTM requirements.

It is worth noting that some older instruments do not include automatic breakdown detection. IEC 60156 states that the circuit applying the test voltage may be opened manually if a transient spark (audible or visible) occurs between the electrodes. This statement is included specifically to cover the use of these older instruments where, if a spark is heard or seen between the electrodes, a breakdown has occurred and the test is complete.

Testing silicone oil

Silicon oil has much higher viscosity than mineral oil, and is more susceptible to the breakdown arc producing carbon track solids. For these reasons, the standards specify special conditions when testing silicone oils:

IEC 60156 reduces the test voltage switch-off time after breakdown detection from the standard 10 ms to 1 ms for silicone oils.

ASTM D877 and D1816 both specify that, for silicone oils, the energy discharged into the breakdown arc must not exceed 20 mJ.