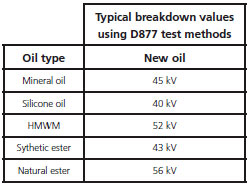

The manufacturer of the insulating fluid normally quotes typical breakdown values for both new and in-service fluid in its data sheets. In addition, the test standards refer to oil condition standards that provide guidance about the acceptability of results.

USA - ASTM and IEEE standards

D877 as already mentioned, is usually only recommended for the acceptance of new oil from a supplier. However, some oil testing laboratories still recommend its use for specific in-service applications. In these cases, a breakdown voltage of 30 kV or more is usually considered to be acceptable, with values below 25 kV unacceptable. Values between 25 and 30 kV are considered questionable. For new oil, a minimum value of 30 kV is normally specified.

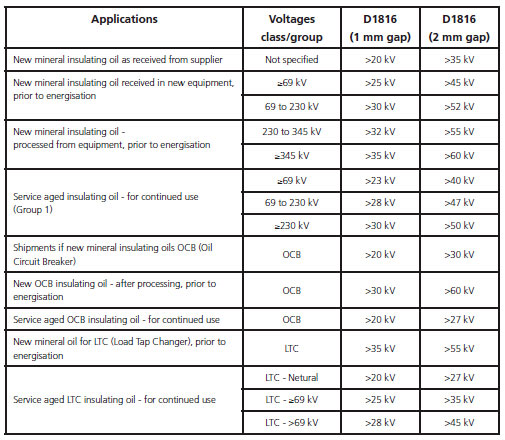

D1816 is more widely used and is accepted by the IEEE as the test method to be used for dielectric breakdown testing for the acceptance and maintenance of insulating oil. The IEEE C57.106 standard incorporates the D1816 limits - which are shown below - for new and in-service oil. Note that the values provided in this table are for mineral oil.

IEEE C57.106-2006

IEEE Guide for acceptance and maintenance of insulating oil in equipment

International IEC standards

IEC 60156 uses acceptance values that are contained in two further standards, IEC 60296 and IEC 60422.

IEC 60296 - Fluids for electrotechnical applications - Unused mineral insulating oils for transformers and switchgear. As its title indicates, this standard applies only to new, unused oil as received from the manufacturer, which must have a dielectric breakdown voltage of 30 kV or more, determined using the IEC 60156 test method. Oil that has been vacuum filtered in a laboratory must have a minimum dielectric breakdown voltage of 70 kV.

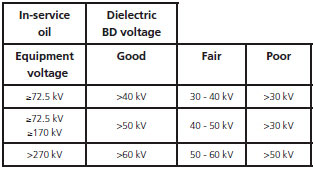

IEC 60422 - Mineral insulating oils in electrical equipment - Supervision and maintenance guide. This standard prescribes acceptable dielectric breakdown values for new oil (after filling but before energising) and for in-service oil. The values are:

The IEC recommends that if values are in the "fair" range, testing should be performed more frequently, and that the test results should be crosschecked with other testing methods. If the test results are in the "poor" range, the oil must be brought back into a good state by reconditioning. This might, for example, involve filtering and drying the oil.