EXPLANATION

This test method provides an indication of thermal oxidative stability of distillate fuels when heated to high temperatures that simulate those that may occur in some types of recirculating engine or burner fuel delivery systems. Results have not been substantially correlated to engine or burner operation. The test method can be useful for investigation of operational problems related to fuel thermal stability. When the test method is used to monitor manufacture or storage of fuels, changes in filter rating values can indicate a relative change in inherent stability. Storage stability predictions are more reliable when correlated to longer term storage tests, for example, Test Method ASTM D4625, or other lower temperature, long-term tests.

The test method uses a filter paper with a nominal porosity of 11 μm, which will not capture all of the sediment formed during aging but allows differentiation over a broad range. Reflectance ratings are also affected by the color of filterable insolubles, which may not correlate to the mass of the material filtered from the aged fuel sample. Therefore, no quantitative relationship exists between the pad rating and the gravimetric mass of filterable insolubles.

The test method is suitable to all No. 1 and No. 2 grades in Specifications ASTM D396, ASTM D975, ASTM D2880, and ASTM D3699, and for grades DMX and DMA in Specification ASTM D2069. It is also suitable for similar fuels meeting other specifications. This test method is not suitable for fuels whose flash point, as determined by Test Methods ASTM D56, ASTM D93, or ASTM D3828, is less than 38° C. This test method is also not suitable for fuels containing residual oils.

TEST SUMMARY

Two 50-mL volumes of filtered middle distillate fuel are aged for 90 or 180 min at 150° C in open tubes with air exposure. After aging and cooling, the fuel samples are filtered and the average amount of filterable insolubles is estimated by measuring the light reflectance of the filter pads. The 100 and 0 % extremes of the reflectance rating are defined by an unused filter pad and a commercial black standard, respectively.

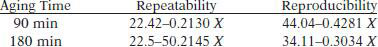

TEST PRECISION

Where X is the average of two results in percentage reflectance.

This test method bias cannot be determined since no accepted reference material is available.