EXPLANATION

This test method is used for determining wear properties and coefficient of friction of lubricating greases at selected temperatures and loads specified for use in applications where high-speed vibrational or start-stop motions are present for extended periods of time under initial high Hertzian point contact pressures. This test method has found application in qualifying lubricating greases used in constant velocity joints of front-wheel-drive automobiles and lubricating greases used in roller bearings.

Following conditions are used: 200 N test load, 50 Hz frequency, 1.00 mm stroke amplitude, 2-h duration, and temperature of ambient to 280° C. Other test loads (10 to 1400 N), frequencies (5 to 500 Hz), and stroke amplitudes (0.1 to 3.30 mm) can be used, if specified. The wear scar on the test ball and coefficient of friction are measured. If a profilometer is available, a trace of the wear scar on the disk can also be used to obtain additional wear information.

TEST SUMMARY

This test method is performed on an SRV test machine using a test ball oscillated under constant load against a test disk.

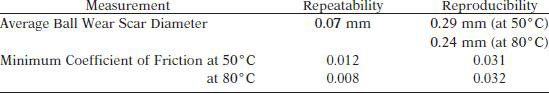

TEST PRECISION

This test method has no bias.