(Equivalent Test Method: DIN 51834)

EXPLANATION

This test method can be used to determine anti-wear properties and coefficient of friction of extreme pressure (EP) lubricating oils at selected temperatures and loads in applications for protecting against wear when subjected to high-frequency, linear oscillation motion. It has found application as a screening test for lubricants used in gear or cam/follower systems. No correlation is claimed between the results of this test method and field performance. This test method can also be used to determine the ability of a non-EP lubricating oil to protect against wear and its coefficient of friction under similar test conditions.

TEST SUMMARY

This test method is performed on an SRV test machine using a test ball oscillated at constant frequency and stroke amplitude and under controlled load against a test disk that has been moistened with the lubricant specimen. The platform to which the test disk is attached is held at a constant temperature. The friction force is measured by a piezo-electric device in the test disk assembly. Peak values of coefficient of friction are determined and recorded as a function of time. After a pre-set test period, the test machine and chart recorder are stopped and the wear scar on the ball is measured. If a profilometer is available, a trace of wear scar on the test disk can be used to obtain additional wear information.

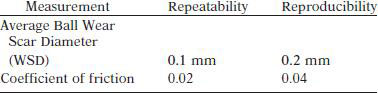

TEST PRECISION

This test method has no bias.