(Equivalent Test Methods: IP 146, ISO 6247, DIN 51566, and JIS K 2518)

EXPLANATION

The tendency of oils to foam can be a serious problem in systems such as high-speed gearing, high-volume pumping, and splash lubrication. Inadequate lubrication, cavitation, and overflow loss of lubricant may lead to mechanical failure. This test method is valuable in the selection of oils suitable for such operating conditions.

Norton Stones and Mott metal diffusers may be used. Both give equivalent results for most oil samples; though there may be some exceptions. Recent industry experience shows that even the so-called "calibrated" Norton Stones fail to pass porosity and permeability requirements sometimes 100 % of the time. On the other hand, Mott metal diffusers have a 100 % acceptance rate. Hence, it is preferable to use the metal diffusers, even though they cost more than the stones.

ASTM has recently formed an adhoc committee to recommend on the choice of diffusers. It is expected that this group will recommend that the stone diffusers should not be allowed in this test.

TEST SUMMARY

The sample maintained at a temperature of 24° C (75° F) is blown with air at a constant rate for 5 min, then allowed to settle for 10 min. The volume of foam is measured at the end of both periods. The test is repeated on a second sample at 93.5° C (200° F), and then, after collapsing the foam, at 24° C (75° F).

It is critical that the diffusers be first tested for maximum pore diameters and permeability as given in the mandatory annex to the test method. A schedule for cleaning and replacing the diffusers should be established. A 1994 ASTM crosscheck showed serious disagreement in testing the diffuser porosity.

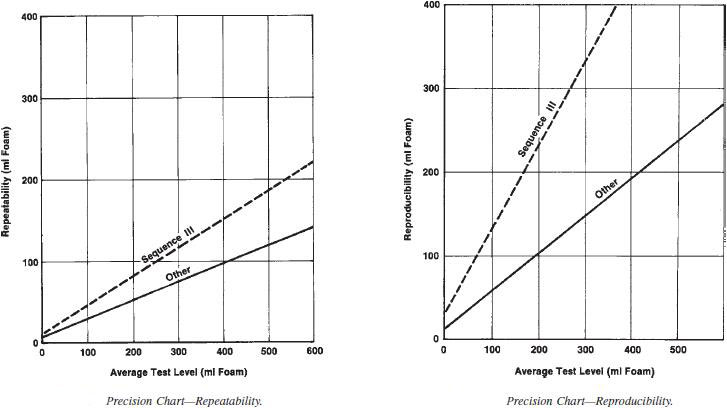

TEST PRECISION