EXPLANATION

The results from these tests are useful as guides in determining the tendency of a water-based metal working coolant to produce foam under low or high shear conditions. No correlation with changes in heat transfer, pumpability, or other factors affected by foam is intended. The foam generated by any given industrial process depends on the method by which the foam is generated, and may not be directly proportional to that produced by this controlled laboratory test method. The foam generated at the specified test temperature will not necessarily predict the foaming tendency of the liquid at some other use temperature. There are two test methods for this analysis. Both measure the increase in volume of a low viscosity aqueous liquid (<3 cSt at 40° C) due to its tendency to foam under high shear conditions in Test Method ASTM D3519 and at low shear conditions in Test Method ASTM D3601.

TEST SUMMARY

In Test Method ASTM D3519 procedure, the test fluid is blended for 30 s using a commercial type blender at 25 +/- 1 ° C agitating between 4000 and 13 000 r/min. The preferred range would be 8000 +/- 1000 r/min.

In Test Method ASTM D3601 procedure, the test fluid is vigorously shaken at 25 +/- 1 ° C.

At the end in both the procedures the increase in height of the test fluid is measured.

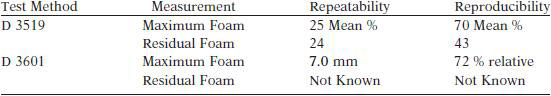

TEST PRECISION

The bias of either of these two test methods is not available.