EXPLANATION

This test commonly known as the "Sequence IV" foam test is the high temperature version of Test Method ASTM D892. This was originally a Ford test, which has now been accepted by all OEMs in a slightly modified form. The test determines the foaming characteristics of lubricating oils at 150° C. This is expected to mimic operations in high-speed gearing, high volume pumping, and splash lubrication.

TEST SUMMARY

A measured quantity of sample is heated to 49° C for 30 min, allowed to cool to room temperature, then tested for foaming characteristics at 150° C. The sample is transferred to a 1000-mL graduate cylinder and aerated with a metal (Mott) diffuser at 200 mL/min dry air for 5 min. The amount of foam generated prior to disconnecting the air, the amount of foam at 5 s after disconnecting the air, the time for the foam to collapse, and the amount of foam remaining after 10 min is determined.

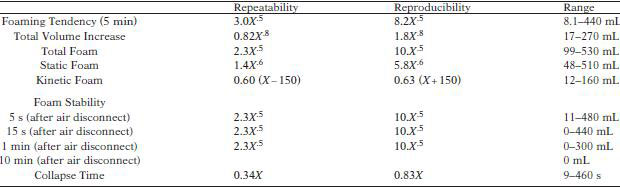

TEST PRECISION

This table is Table 1 in Test Method ASTM D6082-06.