EXPLANATION

A change in filtration performance after storage, pretreatment, or commingling can be indicative of changes in fuel condition. Relative filterability of fuels may vary depending on filter porosity and structure and may not always correlate with results from this test method. Causes of poor filterability in industrial/refinery filters include fuel degradation products, contaminants picked up during storage or transfer, incompatibility of commingled fuels, or interaction of the fuel with the filter media. Any of these could correlate with orifice or filter system plugging, or both.

This test method is applicable to distillate fuel oils within the viscosity range from 1.70 to 6.20 cSt at 40° C. ASTM specification fuels falling within the scope of this test method are Specification ASTM D396, Grade Nos. 1 and 2, Specification ASTM D975, Grades 1-D, low sulfur 1-D, 2-D, and low sulfur 2-D, and Specification ASTM D2880, Grade Nos. 1-GT and 2-GT. This test method is not applicable to fuels that contain undissolved water.

TEST SUMMARY

A sample is passed at a constant rate 20 mL/min through a standard porosity filter medium. The pressure drop across the filter and the volume of filtrate are monitored. The test is concluded either when the pressure drop across the filter exceeds 170 kPa or when 300 mL have passed through the filter. It is not necessary to verify apparatus performance prior to each test. But verification of the apparatus is required when there is a doubt of a test result, or when the apparatus has not been used for three months or more.

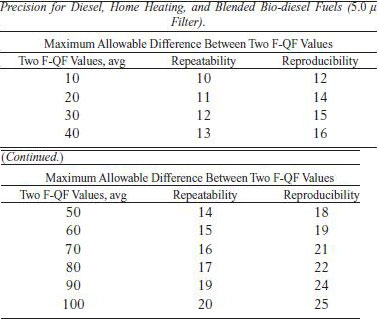

TEST PRECISION