(Equivalent Test Methods: IP 131, ISO 6246, DIN 51784, JIS K 2261, and AFNOR M07-004)

EXPLANATION

High gum can cause induction-system deposits and sticking of intake valves, and in most instances it can be assumed that low gum will ensure absence of induction-system difficulties. However, the test by itself is not correlative to induction system deposits. The test is applied to motor gasolines to measure the oxidation products formed in the sample prior to or during the comparatively mild conditions of the test procedure. Since many motor gasolines are purposely blended with nonvolatile oils or additives, the heptane extraction step is necessary to remove these from the evaporation residue so that the deleterious material, gum, may be determined. With respect to aviation turbine fuels, large quantities of gum are indicative of contamination of fuel by higher boiling oils or particulate matter and generally reflect poor handling practices in distribution downstream of the refinery.

TEST SUMMARY

A measured quantity of fuel is evaporated under controlled conditions of temperature and flow of air or steam. For aviation gasoline and aircraft turbine fuel, the resulting residue is weighed and reported. For motor gasoline, the residue is weighed before and after extracting it with n-heptane, and the results reported.

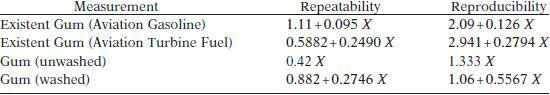

TEST PRECISION

Where X is the average of the results being compared.

These precision values were measured on motor gasoline samples only, and do not necessarily reflect the values obtainable on other product types.

The bias of this test method has not been determined.