(Equivalent Test Methods: IP 421, DIN 51581, and CEC-L14-A88)

EXPLANATION

With the introduction of a maximum volatility limit in European crankcase lubricant specifications there was a requirement for a volatility test with acceptable precision limits, since volatility limits may have a significant impact on the formulation and ultimate production costs. This test method is based on the principle of loss of mass at constant temperature under a constant stream of air. Standardization of the equipment is necessary to maintain the required precision and is obtained by checking the value with a datum oil of known value. This test method described, relates to one set of operating conditions but may be readily adapted to other conditions if required.

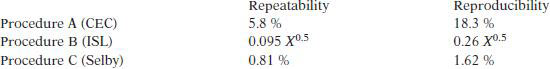

Procedure A is the original DIN and CEC method which uses Wood's metal as a heating medium. Procedure B is the automated ISL method which uses a non-Wood's metal heating method. Procedure C called Selby Noack method also does not use the Wood's metal. It can also collect the evolved gases for separate analysis if desired. Noack results determined using Procedures A and B show consistent differences. Procedure A gives slightly lower results versus Procedure B on formulated engine oils, while Procedure A gives higher results versus procedure B on basestocks. Interlaboratory tests have shown that Procedures A, B, and C yield essentially equivalent results with a correlation coefficient R2 of 0.996.

TEST SUMMARY

The evaporation loss is defined as that mass of oil lost when the sample is heated in a test crucible, through which a constant flow of air is drawn.

A measured quantity of sample is placed in an evaporation crucible which is then heated to 250° C with a constant flow of air drawn through it for 60 min. The loss in mass of the oil is determined. The reproducibility of this test method is dependent on a mandatory use of standard apparatus and procedure.

TEST PRECISION

Several companies have found a correlation of 21.5 % Noack volatility to be equivalent to 17 % volatility by GC-SD methods (see Test Methods ASTM D2887 or ASTM D5480).

NOTES

Attempts have been made to correlate Noack results with thermogravimetry, high temperature-GCD, and MCRT. See oil volatility GCD Test Method ASTM D5480 and TGA volatility Test Method ASTM D6375.

SAFETY

A great deal of concern has been expressed both in ASTM and IP regarding the use and handling of hazardous material used in the Noack test. The safety concerns are two-fold: (a) volatilization of heated oil, and (b) release of lead, tin, bismuth, and cadmium from the Wood's metal heating block at 250° C during testing. These are highly toxic, chronic poisons. An incident in Europe showed contamination of laboratory benches around the Noack analyzers with these metals. The analyzers must be operated in well-ventilated hoods. Further specific precautions may be necessary to prevent exposure to these toxic metal fumes and oil vapors. Savant Laboratory and ISL are now selling commercial instruments which do not use the Wood's metal.