EXPLANATION

Measurement of changes in the volume and hardness of an elastomer that occur from immersion in a lubricating grease or fluid provide a means of evaluating relative compatibility. Much of this test method is derived from Test Method ASTM D471 and Federal Test Method 791C/3603.5. Although this test method was specifically developed for evaluating greases used in automotive applications, it can also be applied to lubricants used in industrial applications. The volume and hardness-change values determined by this test method do not duplicate similar changes that occur in elastomeric seals under actual service conditions. However, they can be correlated in many instances.

Some lubricant specifications may require different test conditions, such as longer durations or lower or higher temperatures. In such cases, the precision values stated in this method do not apply. This test method can also be used to evaluate the compatibility of greases with rubber products not in standard sheet form.

TEST SUMMARY

A prepared elastomer coupon is measured for initial hardness (Durometer A), density or relative density, and volume by water displacement. The coupon is immersed in test grease or fluid and aged for 70 hours at either 100° C (for chloroprene and similar flex-resistant elastomers) or at 150° C (for nitrile and similar heat resistant elastomers) or at other conditions required by the lubricant specifications. The resulting change in hardness and volume is determined.

Because of possible degradation, in order to ensure acceptable precision in this test method, neither test greases nor test elastomers should be more than approximately one year old.

If necessary, precautions should be taken to maintain integrity of the elastomers by storing under special conditions described in the test method.

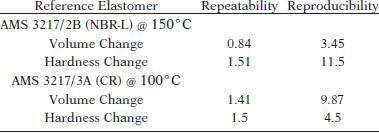

TEST PRECISION

Where volume change is in units of percentage points, and hardness change is in units of Durometer A units.

This test method has no bias because the values for volume change and hardness change can be defined only in terms of the test method.