When an oil is heated up, its viscosity will decrease. The formulation of the oil is such that it keeps the following in perspective: the oil must be able to be pumped through the system as fast as possible when cold on start-up in order to lubricate all components within a few seconds of the engine starting. The same oil must then be able to supply sufficient lubrication to all components at normal operating temperature. Different environments will place different demands on the lubricating oil but it must remain 'thin' (low viscosity) enough when cold so that it can flow and 'thick' (high viscosity) enough when hot to keep moving parts separated.

These characteristics allow engine oils to supply sufficient viscosity at all normal operating temperatures. The minute these temperatures go outside the parameters of the oil's design the lubrication efficiency will be compromised. For example, if an oil with too high a starting viscosity is used, it will take a relatively long time for the oil to reach all the components on cold start-up. If an oil with a very low viscosity is used it will get to all the components within the engine very quickly on start-up but be too thin for adequate lubrication at operating temperature. Multigrade oils contain base stocks and additives that allow them to perform in exactly this manner - not too thick on start-up and not too thin at operating temperature. This is why the correct choice of oil for a vehicle in a particular environment is critical to engine operation and life expectancy. This selection should always be made in conjunction with the OEM.

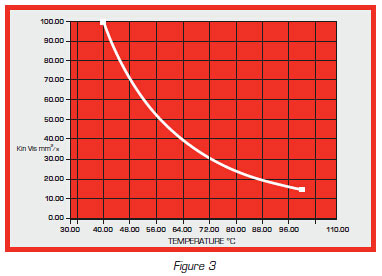

As mentioned previously, an oil's viscosity will decrease as temperature increases. A standard 15W40 multigrade engine oil, the grade predominantly used in Southern Africa, has a starting viscosity at 40°C of approximately 110mm 2 /s (centistokes) and an operating viscosity at 100°C of approximately 14.5mm2/s (see Figure 3).

A standard water cooled engine should operate with a cooling system temperature between 80°C and 90°C. Considering that the oil operating temperature should be 10°C to 15°C above the coolant temperature, then the oil operating temperature should be within 90°C to 105°C but should not exceed 105°C.

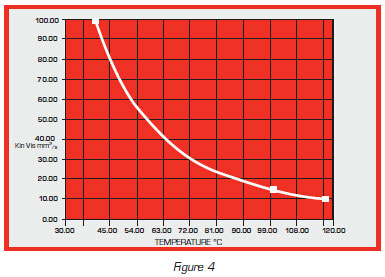

Another general rule that can be applied to the operating viscosity of engine oil is that, if the operating viscosity of the oil goes below 10mm2/s, then the oil is too thin to lubricate all components within the engine adequately (see Figure 4).

In an engine there are two main lubrication regimes that exist, hydrodynamic lubrication (pressurised lubrication to the crankshaft) and boundary lubrication (non-pressurised lubrication surrounding the pistons). In both cases the viscosity thickness of the oil is important but of primary importance for hydrodynamic lubrication.

Taking into account that as the engine warms up components expand with heat, the engine is designed in such a way that, at optimum operating temperature, components would expand to the optimum size. If the optimum temperatures are not achieved then expansion will be either excessive or insufficient and can cause complications in the running efficiencies of the engine.