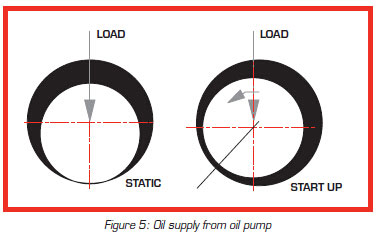

Hydrodynamic lubrication works in the following way: oil is pumped from the oil pump through a heat exchanger and then a filtration system to the crankshaft under pressure. At operating temperature this process occurs almost immediately (see Figure 5).

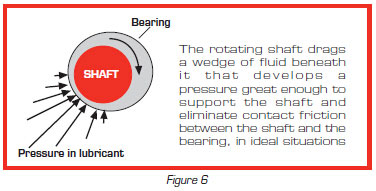

As rotation commences oil pressure which is built up between the bearing and the crankshaft journal creates an oil wedge (see Figure 6).

In a cold start-up situation the same occurs except that the oil is substantially thicker due to the fact that it is cold and therefore cannot pass through the filter media efficiently. This means that the filter goes into bypass, allowing the oil to move through the system in a partially or totally unfiltered state. The filter or filter housing is designed in such a way as to allow this to happen. There is either a bypass valve in the filter itself or one is built into the filter housing. This bypass valve also works as a safety mechanism in the event that the filter was to block, allowing oil supply to continue to all the engine components. As the operating temperature of the oil and the engine increases, the viscosity of the oil decreases and the bypass valves reseat themselves, allowing the oil to move through the filter media.