A boundary lubrication regime lubricates all additional components within the engine that are not lubricated under pressure. The components that fall into this category are pistons, piston rings, camshaft lobes, cam followers, rockers, valves, timing drive train, etc. (see Figure 7).

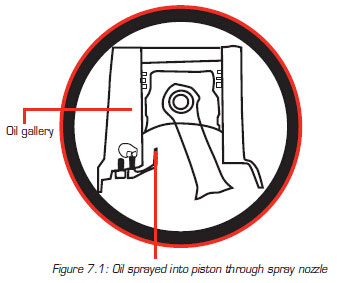

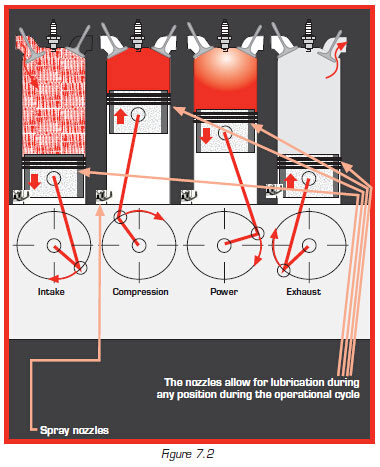

Boundary lubrication is reliant on high-volume replenishment for lubrication to work efficiently and the fact that engine oils contain anti-wear additives that reduce friction and wear even when a full hydrodynamic film of oil is not present. High-volume replenishment can be achieved by means of spray nozzles or splash-feed. All new generation engines are fitted with piston cooling spray nozzles to ensure proper piston cooling and lubrication to the piston skirts. This oil then coats the components during movement in order to reduce friction, at which time the lubrication is generally forced away from the components but continuously replaced with a fresh supply of oil being splashed or sprayed into the affected area (see Figures 7.1 and 7.2).