EXPLANATION

At high temperatures aviation turbine fuels can oxidize and produce insoluble deposits that are detrimental to aircraft propulsion systems. Very low copper levels in excess of 50 μg / kg can significantly accelerate this thermal instability. Since naval shipboard aviation fuel delivery systems contain copper-nickel piping this can increase the copper levels in the fuel. Thus, this method can be used to check the copper levels in aviation turbine fuel samples taken on shipboard, in refineries, and at fuel storage depots. This test method covers the copper range of 5 - 100 μg / kg. Copper concentration above this level may also be determined by diluting the samples with kerosene to bring the copper level in the above range.

TEST METHOD SUMMARY

Typically 10 μL of the sample is pipetted onto a platform in the graphite furnace. The furnace is heated to low temperature to dry the sample completely without spattering. It is next heated to moderate temperature to eliminate excess sample matrix, and finally heated very rapidly to a temperature high enough to volatilize copper. In this step the amount of light absorbed by the copper atoms is measured by the spectrometer over a specified period of time. The integrated absorbance produced by copper in the sample is compared to a calibration curve constructed from the measured value for organo-metallic standards.

The char step in the heating program is used to eliminate as much of the matrix as possible before the atomization step to reduce undissociated molecular particles from the sample matrix. Most spectrometers are also equipped with back-ground correction capabilities to further control possibilities of erroneous results due to molecular absorption.

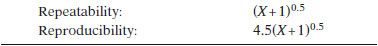

TEST PRECISION

Where X is the average of two results in μg / kg.

No statement regarding bias of this test method can be made since there is no accepted reference material for this analysis.