EXPLANATION

This test method provides a cooling time versus temperature pathway which is directly proportional to physical properties such as the hardness obtainable upon quenching of a metal. These results may be used as a guide in heat treating oil selection or comparison of quench severities of different heat treating of new or used oils. This test is designed to evaluate quenching oils in a nonagitated system. There is no correlation between these test results and the results obtained in agitated systems.

TEST SUMMARY

The nickel alloy probes assembly's cooling time versus temperature is determined after placing the assembly in a furnace and heating to 850° C, and then quenching in a heat treating oil. The temperature inside the probe assembly and the cooling times are recorded at selected time intervals to establish a cooling temperature versus time curve. The resulting cooling curve may be used to evaluate quench severity.

The presence of water in a heat treating oil has a major effect upon the results obtained with this test method. If the water content is above 0.01 %, the calibration fluid has to be dried at a minimum temperature of 102° C until water content is at or below 0.01 %. The water content may be determined using the Test Method ASTM D1744.

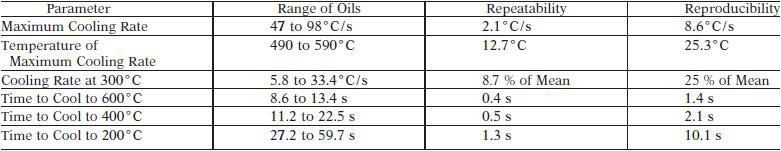

TEST PRECISION

This test method has no bias because the cooling characteristics can be defined only in terms of this test method.