EXPLANATION

During operation of gas turbines and diesel engines, some of the ash-forming substances present in a fuel can lead to high temperature corrosion, as deposition, and fuel system fouling. Fuel contamination specifications vary among the different gas turbine manufacturers. However, without exception, each requires that contaminants must be as low as possible. In most power generation installations, it is the owner's responsibility to verify fuel cleanliness in compliance with turbine manufacturer's warranty specifications. This leads to an on-site analytical instrument performance requirement of below 1.0 mg/kg for several elements. This test method covers such determinations using rotating disk electrode atomic emission spectroscopy.

The test method is applicable to ASTM Grades 0 through 4-GT gas turbine fuels, and Grades Low Sulfur No. 1 and 2-D, and No. 1-D, 2-D, and No. 4-D diesel fuel oils. This test method provides a rapid at-site determination of contamination and corrosive elements ranging from fractions of mg/kg to hundreds of mg/kg in gas turbine and diesel engine fuels so the fuel quality and level of required treatment can be determined. This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine or detect insoluble particles.

TEST SUMMARY

A fuel test specimen is excited by a controlled arc discharge using the rotating disk technique. The radiant energies of selected analytical lines and a reference are collected and stored by way of photomultiplier tubes, charge coupled devices, or other suitable detectors. A comparison is made of the emitted intensities of the elements in the fuel test specimen against those measured with calibration standards. The concentration of the elements present in the fuel test specimen are calculated and displayed.

INTERFERENCES - There are three kinds of interferences possible in this test method.

(1) Most spectral interferences can be avoided by judicious choice of spectral lines. High concentrations of certain elements can have an interfering influence on the spectral lines used for determining trace levels of contaminants. Instrument manufacturers usually compensate for spectral interferences during factory calibration. A background correction system can also be used for this purpose. If neither of these is effective, the necessary corrections shall be made using the computer software supplied by the instrument manufacturer.

(2) Differences in viscosity of fuel samples will cause differences in uptake rate. Internal references of an instrument will compensate for a portion of the differences. The hydrogen 486.10 nm spectral line shall be used for light fuels, and the carbon 387.10 nm spectral line shall be used as an internal reference to compensate for viscosity effects.

(3) When large particles over 10 μm in size are present in the sample, the analytical results will be lower than the actual concentrations they represent. Large particles may not effectively be transported by the rotating disk electrode sample introduction system into the arc, nor will they be fully vaporized.

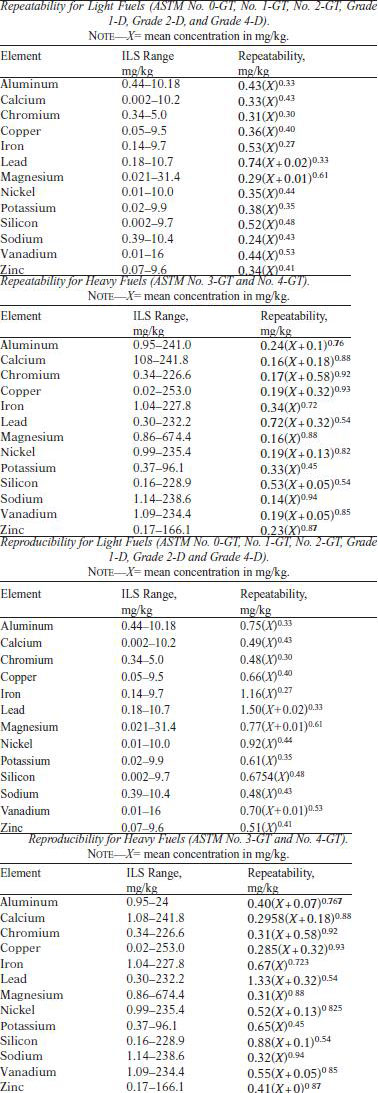

TEST PRECISION

The bias was insignificant for light fuels with the exception of calcium, copper, sodium, and zinc at 5 mg/kg concentration, and for heavy fuels, aluminum and nickel at 30 mg/kg.