(Equivalent Test Methods: IP 50, ISO 2137, and AFNOR T60-132)

EXPLANATION

Cone penetration test provides one measure of the consistency of a grease. These tests cover the full range of NLGI numbers from 000 to 6. They also evaluate the consistency of stiff greases with penetration numbers less than 85. Although no correlation has been developed between cone penetration results and field service, the former results are widely used for specification purposes in users' and suppliers' manufacturing specifications.

Test Method ASTM D937 is aimed at petrolatums, and Test Method ASTM D1403 is used for limited sample quantities.

TEST SUMMARY

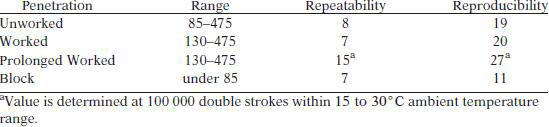

This test method consists of four procedures. For unworked penetration, the cone assembly of the penetrometer is allowed to drop freely into the grease sample at 25° C in a worker cup for 5 s. For worked penetration, the sample at 25° C in a worker cup is subjected to 60 double strokes by the grease worker. The penetration is determined immediately by releasing the cone assembly from the penetrometer and allowing the cone to drop freely into the grease for 5 s. For prolonged work penetration, the procedure is the same as for worked penetration, except that additionally before cone penetration, the sample is subjected to a predetermined number of double strokes in the grease worker. For block penetration, a cube of grease is used and the test is followed as in that for unworked penetration.

In all cases three determinations are made and the average value is reported.

TEST PRECISION