EXPLANATION

Chlorinated compounds can corrode the equipment and poison the refining catalysts. They are also a health hazard when incompletely combusted. Federal regulations mandate that often the chlorine content of used oil must be determined before recycling. This method can be used to determine when a used petroleum product meets or exceeds requirements for total halogen measured as chloride. It is specifically designed for used oils permitting on-site testing at remote locations by nontechnical personnel. Bromide and iodide are also titrated and reported on a molar basis as chlorine. A positive bias will result from samples that contain greater than 3 m / m % total sulfur. Other analytical methods should be used on oils containing high amounts of sulfur.

Method A provides greater or less than estimate of 1000 ppm total chlorine content to meet the regulatory requirements for the used oils. Method B covers the range from 200 to 4000 ppm of total chlorine, with a lower limit of quantitation estimated to be 870 to 1180 ppb.

TEST SUMMARY

The oil sample is dispersed in a hydrocarbon solvent and reacted with a mixture of metallic sodium catalyzed with napthalene and diglyme at ambient temperature. This converts organic halogens to their respective sodium halides which are then extracted into an aqueous buffer, which isthen titrated with mercuric nitrate using diphenyl carbazone as the indicator. The end point of the titration is the formation of the blue-violet mercury diphenylcarbazone complex. Method A uses preset reagent quantities so that the final result clearly indicates pass or fail of the 1000 ppm limit.

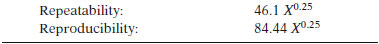

TEST PRECISION

Where X is the method result in mg/kg.

No bias statement for this test method can be made.