ASTM D942 standard test method for oxidation stability of lubricating greases by the oxygen pressure vessel method

5. Apparatus

5.1 Oxidation Pressure Vessel, Sample Dish, Dish Holder, Pressure Gage and Oil Bath as described in detail in the Annex.

NOTE 3 - Other constant-temperature baths may be used if they are equivalent in heat capacity and thermal gradient characteristics to the oil bath described in the Annex and can be shown to maintain the pressure vessel at the prescribed test temperature.

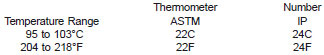

5.2 Thermometer, having a range as shown below and conforming to the requirements as prescribed in Specification E 1 or in the Specifications for IP Standard Thermometers:

6. Material

6.1 Oxygen, of not less than 99.5 % purity.

6.2 (Warning - Since oxygen vigorously accelerates combustion, observe the following procedures: (1) Keep oil and grease away from oxygen at high pressure. Keep oil and grease away from all regulators, gages and control equipment. (2) Use oxygen only with equipment conditioned for oxygen service by careful cleaning to remove oil and grease from area in contact with high pressure oxygen. (3) Keep combustibles away from oxygen and eliminate ignition sources. (4) Keep surfaces clean to prevent ignition or explosion, or both, upon contact with high pressure oxygen. (5) Always use a pressure regulator to deliver oxygen. Release regulator tension before opening oxygen cylinder. (6) All equipment used must be suitable and recommended for oxygen service. (7) Never attempt to transfer oxygen from cylinder in which it is received to any other cylinder prior to use. (8) Do not drop oxygen cylinders. (9) Keep cylinder valve closed when not in use. (10) Stand away from valve when opening cylinder. (11) Do not breathe or use technical grade oxygen for inhalation purposes. (12) See Compressed Gas Association Booklets G-4 and G-4-1(7) for details of safe practice in the use of oxygen.)

6.3 n-Heptane - (Warning - Flammable. Harmful if inhaled. Keep away from heat, sparks, and open flame. Keep container closed. Use with adequate ventilation. Avoid breathing vapor or spray mist. Avoid prolonged or repeated contact with skin.)

6.4 Cleaning Solution, capable of satisfactorily cleaning the glassware used in the test. The criterion for satisfactory cleaning shall be a matching of the quality of that obtained with chromic acid cleaning solutions (fresh chromic acid, 6-h soaking period, rinsing with distilled water and drying) or some other equivalently strong oxidizing non-chromium containing acid cleaning solutions on used sample dishes. (Warning - Causes severe burns. A recognized carcinogen. Strong oxidizer; contact with organic material may cause fire. Hygroscopic.) (Warning - Do not get in eyes, on skin, or on clothing. Avoid breathing vapor or mist. Keep container closed. Use with adequate ventilation. Do not take internally.) For this comparison, visual appearance and mass loss on heating the glassware under test conditions may be used. Detergent cleaning avoids the potential hazards and inconveniences related to handling corrosive chromic acid solutions; this procedure remains the reference cleaning practice and as such may function as an alternate to the preferred procedure, cleaning with detergent solutions.

7. Preparation of Apparatus

7.1 Clean the sample dishes from all contamination from previous runs and from dust settling from the air by washing them with n-heptane and then with a cleaning solution. Follow the final cleaning operation by a thorough tap water rinse, a distilled water rinse, and drying in an oven. Handle the clean dishes only with forceps. (Warning - Handle in well-ventilated area, preferably in a hood. Keep away from heat, sparks, and open flame. Keep container closed when not in use.) (Warning - See 6.3, and avoid skin contact, which may cause severe burns.)

7.2 If lacquer is found after a run, clean the inside of the oxidation pressure vessel and the metal supports for the pressure vessel dishes by immersing in an appropriate solvent capable of removing the lacquer, such as gum solvent as specified in Test Method D525, and scrubbing with a bristle brush followed by drying. Scrub further with water and a fine scouring powder until all the lacquer deposits are removed. Follow the scouring operation by a thorough tap water rinse, a distilled water rinse, and drying in an oven. Handle the clean metal supports only with forceps.