12.1 To make a measurement, follow the manufacturer's operating guidelines when the temperature of the inner electrode is within 60.5°C of the desired test temperature.

12.2 On completing the initial measurement, pour off the liquid, and refill the cell, following the same procedure and exercising the same precautions used in making the first filling, and take another measurement. If the difference in the measurements of the two test specimens is equal to or less than 0.0001, plus 10% of the higher of the two values, no further tests are required, and the reported value for the sample shall be taken as the average of the two measurements. If the difference in the measurements of the two test specimens is greater than 0.0001, plus 10% of the higher of the two values, refill the cell and take a third measurement. If the difference between the third measurement and either the first ors econd is not within 0.0001, plus 10% of the higher of the two values used in this computation, discard these results, reclean the cell, obtain another sample, and repeat the procedure until two measurements from a sample are obtained that do meet the prescribed limits.

13. Procedure - Relative Permittivity

13.1 Measure the capacitance of the test cell with air as the dielectric and then with the cell filled with the liquid. Both measurements should be made at the same temperature. Use these measurements in calculating the relative permittivity from the following equation:

K1 = Cx / Cv

where:

K1 = relative permittivity of the liquid,

Cx = capacitance of test cell with the liquid as the dielectric,and

Cv = capacitance of test cell with air as the dielectric.

14. Report

14.1 Report the following information:

14.1.1 Sample identification,

14.1.2 Type of test cellused,

14.1.3 Measurement procedure: referee,

14.1.4 Average voltage gradient in the sample while under test, in volts permillimeter(volts per mil) (rms),

14.1.5 Frequency of applied voltage,

14.1.6 Temperature of the sample while under test,

14.1.7 Temperature and humidity of the room during test,

14.1.8 Dissipation factor or power factor of the sample, usually expressed as a percentage(%), and

14.1.9 Relative permittivity (dielectric constant) of the sample, when required.

15. Precision and Bias

15.1 Interlaboratory Test Program - An interlaboratory study of dissipation factor in mineral insulating oil was conducted in accordance with Practice E691 in twelve laboratories with four different oils. Each sample was tested using the referee procedure at 25°C and at 100°C. The results are documented in a research report available from ASTM International Headquarters.

15.2 Precision - The precision information given below for referee testing of dissipation factor is for the comparison of two test results, each of which is the average of two test determinations.

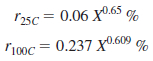

15.2.1 95% Repeatability Limit (within laboratory) - The absolute difference between two results obtained in the same laboratory by the same analyst may be expected to be below these calculated values 95% of the time:

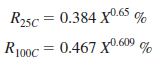

15.2.2 95% Reproducibility Limit(between laboratories) - The absolute difference between two results obtained in different laboratories by different analysts may be expected to be below these calculated values 95% of the time:

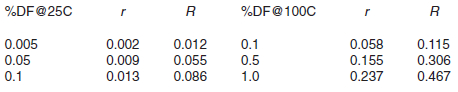

15.2.3 Calculated values of repeatability and reproducibility are shown in the table below:

15.3.1 As there is no accepted reference material available for dissipation factor(or power factor), no bias statement can be made.

15.3.2 As there is no accepted reference available for relative permittivity, no bias statement can be made.