4.1 Dissipation Factor(or Power Factor) - This is a measure of the dielectric losses in an electrical insulating liquid when used in an alternating electric field and of the energy dissipated as heat. A low dissipation factor or power factor indicates low ac dielectric losses. Dissipation factor or power factor may be useful as a means of quality control, and as an indication of changes in quality resulting from contamination and deterioration in service or as a result of handling.

4.1.1 The loss characteristic is commonly measured in terms of dissipation factor(tangent of the loss angle) or of power factor(sine of the loss angle) and may be expressed as a decimal value or as a percentage. For decimal values up to 0.05, dissipation factor and power factor values are equal to each other within about one part in one thousand. In general, since the dissipation factor or power factor of insulating oils in good condition have decimal values below 0.005, the two measurements(terms) may be considered interchangeable.

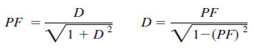

4.1.2 The exact relationship between dissipation factor(D) and power factor(PF) is given by the following equations:

D or PF at 25°C = 0.002 or 0.2%

4.2 Relative Permittivity (Dielectric Constant) - Insulating liquids are used in general either to insulate components of an electrical network from each other and from ground, alone or in combination with solid insulating materials, or to function as the dielectric of a capacitor. For the first use, a low value of relative permittivity is often desirable in order to have the capacitance be as small as possible, consistent with acceptable chemical and heat transfer properties. However, an intermediate value of relative permittivity may sometimes be advantageous in achieving a better voltage distribution of a-c electric fields between the liquid and solid insulating materials with which the liquid may be in series. When used as the dielectric in a capacitor, it is desirable to have a higher value of relative permittivity so the physical size of the capacitor may be as small as possible.

4.3 Theory relating to dielectric measurement techniques and to sources of dielectric loss is given in Test Methods D150.

5. Sampling

5.1 Sample electrical insulating liquids in accordance with Practices D923. Samples to be subjected to this test should preferably be obtained through a closed system. If exposed to atmospheric conditions, it is preferable to take the sample when the relative humidity is 50% or less. If it is not feasible, the length of time the sample is exposed to atmospheric conditions must be kept to a minimum.

5.2 Some liquids, in certain applications, require special handling and processes in the sampling, and these will be found in the governing procedures. Consult such procedures before samples are taken.

5.3 The quantity of sample taken for this test shall be sufficient for at least three separate determinations of loss characteristics and relative permittivity.

5.4 The loss characteristic measurement (dissipation factor or power factor) may be affected by contamination introduced during sampling and subsequent handling.