12. Report

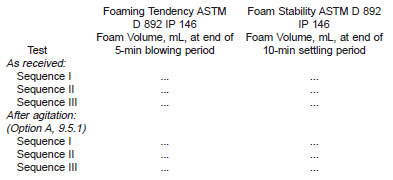

12.1 Report the data in the following manner:

12.2 For the purpose of reporting results, when the bubble layer fails to completely cover the oil surface and a patch or eye of clear fluid is visible, the value shall be reported as nil foam.

13. Precision and Bias

13.1 Precision - The precision values in this statement were determined in a cooperative laboratory program.

13.1.1 Repeatability - The difference between successive results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method exceed the following values in only one case in twenty (see Fig. 3).

13.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, exceed the following values in only one case in twenty (see Fig. 4).

NOTE 13 - The dashed lines in Fig. 3 and Fig. 4 are for foam stability of Sequence III and the solid lines are for foam height for Sequences I, II, and III and foam stability for Sequences I and II.

13.1.3 For those oils which have been tested by Option A (10.5.1), no precision statement is yet available.

NOTE 14 - The majority of the results in the cooperative work that led to Option A were nil foam; hence, no precision statement can be calculated.

13.2 Bias - Since there is no accepted reference material suitable for determining the bias for the procedure for measuring foaming characteristics in Test Method D 892, bias cannot be determined.

14. Keywords

14.1 foam (foaming)