ASTM D86 for distillation of petroleum products at atmospheric pressure

10. Procedure

10.1 Record the prevailing barometric pressure.

10.2 Groups 1 and 2 - Fit a low range thermometer provided with a snug-fitting cork or stopper of silicone rubber, or equivalent polymeric material, tightly into the neck of the sample container and bring the temperature of the sample to the temperature indicated in Table 1.

10.3 Groups 1, 2, 3, and 4 - Check that the temperature of the sample is as shown in Table 1. Pour the specimen precisely to the 100-mL mark of the receiving cylinder, and transfer the contents of the receiving cylinder as completely as practical into the distillation flask, ensuring that none of the liquid flows into the vapor tube.

NOTE 13 - It is important that the difference between the temperature of the specimen and the temperature of the bath around the receiving cylinder is as small as practically possible. A difference of 5°C can make a difference of 0.7 mL.

10.3.1 Groups 3 and 4 - If the sample is not fluid at ambient temperature, it is to be heated to a temperature between 9 and 21°C above its pour point (Test Methods D 97, D 5949, D 5950, or D 5985) prior to analysis. If the sample has partially or completely solidified in the intervening period, it shall be vigorously shaken after melting, and prior to sampling, to ensure homogeneity.

10.3.1.1 If the sample is not fluid at ambient temperatures, disregard the temperature range shown in Table 1 for the receiving cylinder and sample. Prior to analysis, heat the receiving cylinder to approximately the same temperature as the sample. Pour the heated specimen precisely to the 100-mL mark of the receiving cylinder, and transfer the contents of the receiving cylinder as completely as practical into the distillation flask, ensuring that none of the liquid flows into the vapor tube.

NOTE 14 - Any material that evaporates during the transfer will contribute to the loss; any material that remains in the receiving cylinder will contribute to the observed recovery volume at the time of the IBP.

10.4 If the sample can be expected to demonstrate irregular boiling behavior, that is, bumping, add a few boiling chips to the specimen. The addition of a few boiling chips is acceptable for any distillation.

10.5 Fit the temperature sensor through a snug-fitting device, as described in 6.4, to mechanically center the sensor in the neck of the flask. In the case of a thermometer, the bulb is centered in the neck and the lower end of the capillary is level with the highest point on the bottom of the inner wall of the vapor tube (see Fig. 5). In the case of a thermocouple or resistance thermometer, follow the manufacturer's instructions as to placement (see Fig. 6).

NOTE 15 - If vacuum grease is used on the mating surface of the centering device, use the minimum amount of grease that is practical.

10.6 Fit the flask vapor tube, provided with a snug-fitting cork or rubber stopper of silicone, or equivalent polymeric material, tightly into the condenser tube. Adjust the flask in a vertical position so that the vapor tube extends into the condenser tube for a distance from 25 to 50 mm. Raise and adjust the flask support board to fit it snugly against the bottom of the flask.

10.7 Place the receiving cylinder that was used to measure the specimen, without drying the inside of the cylinder, into its temperature-controlled bath under the lower end of the condenser tube. The end of the condenser tube shall be centered in the receiving cylinder and shall extend therein for a distance of at least 25 mm, but not below the 100-mL mark.

10.8 Initial Boiling Point:

10.8.1 Manual Method - To reduce evaporation loss of the distillate, cover the receiving cylinder with a piece of blotting paper, or similar material, that has been cut to fit the condenser tube snugly. If a receiver deflector is being used, start the distillation with the tip of the deflector just touching the wall of the receiving cylinder. If a receiver deflector is not used, keep the drip tip of the condenser away from the wall of the receiving cylinder. Note the start time. Observe and record the IBP to the nearest 0.5°C (1.0°F). If a receiver deflector is not being used, immediately move the receiving cylinder so that the tip of the condenser touches its inner wall.

10.8.2 Automated Method - To reduce evaporation loss of the distillate, use the device provided by the instrument manufacturer for this purpose. Apply heat to the distillation flask and contents with the tip of the receiver deflector just touching the wall of the receiving cylinder. Note the start time. Record the IBP to the nearest 0.1°C (0.2°F).

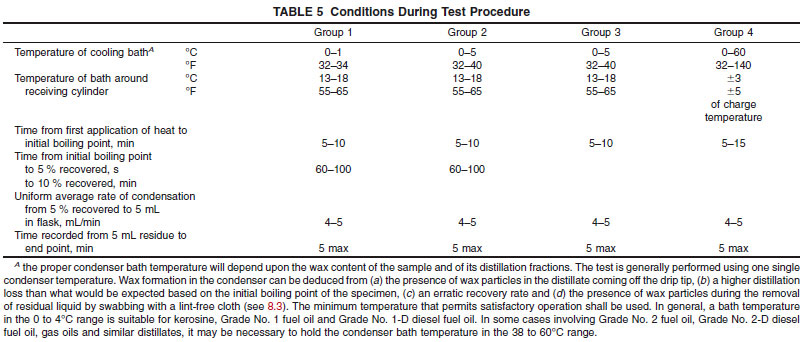

10.9 Regulate the heating so that the time interval between the first application of heat and the IBP is as specified in Table 5.

10.10 Regulate the heating so that the time from IBP to 5 or 10 % recovered is as indicated in Table 5.

10.11 Continue to regulate the heating so that the uniform average rate of condensation from 5 or 10 % recovered to 5 mL residue in the flask is 4 to 5 mL per min. (Warning - Due to the configuration of the boiling flask and the conditions of the test, the vapor and liquid around the temperature sensor are not in thermodynamic equilibrium. The distillation rate will consequently have an effect on the measured vapor temperature. The distillation rate shall, therefore, be kept as constant as possible throughout the test.)

NOTE 16 - When testing gasoline samples, it is not uncommon to see the condensate suddenly form non-miscible liquid phases and bead up on the temperature measuring device and in the neck of the boiling flask at a vapor temperature of around 160°C. This may be accompanied by a sharp (about 3°C) dip in the vapor temperature and a drop in the recovery rate. The phenomenon, which may be due to the presence of trace water in the sample, may last for 10 to 30 s before the temperature recovers and the condensate starts flowing smoothly again. This point is sometimes colloquially referred to as the Hesitation Point.

10.12 Repeat any distillation that did not meet the requirements described in 10.9, 10.10, and 10.11.

10.13 If a decomposition point, as described in 3.1.3, is observed, discontinue the heating and proceed as directed in 10.17.

10.14 In the interval between the IBP and the end of the distillation, observe and record data necessary for the calculation and reporting of the results of the test as required by the specification involved, or as previously established for the sample under test. These observed data can include temperature readings at prescribed percentages recovered or percentages recovered at prescribed temperature readings, or both.

10.14.1 Manual Method - Record all volumes in the graduated cylinder to the nearest 0.5 mL, and all temperature readings to the nearest 0.5°C (1.0°F).

10.14.2 Automated Method - Record all volumes in the receiving cylinder to the nearest 0.1 mL, and all temperature readings to the nearest 0.1°C (0.2°F).

10.14.3 Group 1, 2, 3, and 4 - In cases in which no specific data requirements have been indicated, record the IBP and the EP (FBP) or the dry point, or both, and temperature readings at 5, 15, 85, and 95 % recovered, and at each 10 % multiple of volume recovered from 10 to 90, inclusive.

10.14.3.1 Group 4 - When a high range thermometer is used in testing aviation turbine fuels and similar products, pertinent thermometer readings can be obscured by the centering device. If these readings are required, perform a second distillation in accordance with Group 3. In such cases, reading from a low range thermometer can be reported in place of the obscured high range thermometer readings, and the test report shall so indicate. If, by agreement, the obscured readings are waived, the test report shall so indicate.

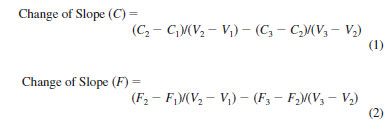

10.14.4 When it is required to report the temperature reading at a prescribed percent evaporated or recovered for a sample that has a rapidly changing slope of the distillation curve in the region of the prescribed percent evaporated or recovered reading, record temperature readings at every 1 % recovered. The slope is considered rapidly changing if the change in slope (C) of the data points described in 10.14.2 in that particular area is greater than 0.6 (change of slope (F) is greater than 1.0) as calculated by Eq 1 (Eq 2).

where:

C1 = temperature at the volume % recorded one reading prior to the volume % in question, °C,C2 = temperature at the volume % recorded in question, °C,

C3 = temperature at the volume % recorded following the volume % in question, °C,

F1 = temperature at the volume % recorded one reading prior to the volume % in question, °F,

F2 = temperature at the volume % recorded in question, °F,

F3 = temperature at the volume % recorded following the volume % in question, °F,

V1 = volume % recorded one reading prior to the volume % in question,

V2 = volume % recorded at the volume % in question, and

V3 = volume % recorded following the volume % in question.

10.15 When the residual liquid in the flask is approximately 5 mL, make a final adjustment of the heat. The time from the 5 mL of liquid residue in the flask to the EP (FBP) shall be within the limits prescribed in Table 5. If this condition is not satisfied, repeat the test with appropriate modification of the final heat adjustment.

NOTE 17 - Since it is difficult to determine when there is 5 mL of boiling liquid left in the flask, this time is determined by observing the amount of liquid recovered in the receiving cylinder. The dynamic holdup has been determined to be approximately 1.5 mL at this point. If there are no front end losses, the amount of 5 mL in the flask can be assumed to correspond with an amount of 93.5 mL in the receiving cylinder. This amount has to be adjusted for the estimated amount of front end loss.

10.15.1 If the actual front end loss differs more than 2 mL from the estimated value, the test shall be rerun.

10.16 Observe and record the EP (FBP) or the dry point, or both, as required, and discontinue the heating.

NOTE 18 - Groups 1 and 2, once the final heat adjustment is made, the vapor temperature/thermometer reading will continue to increase. As the distillation nears the end point (final boiling point) the distillation typically achieves dry point first. After the dry point has been achieved the vapor temperature/thermometer reading should continue to increase. The bottom of the flask will be dry but the sides and neck of the flask and the temperature sensor will still have vapor condensate present. The vapor condensate may have the appearance of a white cloud of fumes. This vapor condensate/cloud of fumes should totally engulf the temperature-measuring sensor before the vapor temperature starts to decrease. If these observations do not occur, the end point may not have been reached. It would be advisable to repeat the test adding additional heat to the final heat adjustment. Typically the vapor temperature will continue to rise as the dry point is reached and the vapor cloud engulfs the temperature-measuring sensor. When the end point is near, the rate of temperature increase will slow and level off. Once the endpoint is reached the vapor temperature will start and continue to decrease. If the vapor temperature starts to decrease but then increases and repeats this cycle while the vapor temperature continues to increase you have added too much heat to the final heat adjustment. If this is the case, it would be advisable to repeat the test lowering final heat setting.

Groups 3 and 4, many Group 3 and 4 samples will have the same distillation characteristics in regards to dry point and endpoint as Groups 1 and 2. With samples that contain higher temperature boiling materials it may not be possible to detect a dry point or an end point before the decomposition point occurs.

10.17 Allow the distillate to drain into the receiving cylinder, after heating has been discontinued.

10.17.1 Manual Method - While the condenser tube continues to drain into the graduated cylinder, observe and note the volume of condensate to the nearest 0.5 mL at 2 min intervals until two successive observations agree. Measure the volume in the receiving cylinder accurately, and record it to the nearest 0.5 mL.

10.17.2 Automated Method - The apparatus shall continually monitor the recovered volume until this volume changes by no more than 0.1 mL in 2 min. Record the volume in the receiving cylinder accurately to the nearest 0.1 mL.

10.18 Record the volume in the receiving cylinder as percent recovery. If the distillation was previously discontinued under the conditions of a decomposition point, deduct the percent recovered from 100, report this difference as the sum of percent residue and percent loss, and omit the procedure given in 10.19.

10.19 After the flask has cooled and no more vapor is observed, disconnect the flask from the condenser, pour its contents into a 5-mL graduated cylinder, and with the flask suspended over the cylinder, allow the flask to drain until no appreciable increase in the volume of liquid in the cylinder is observed. Measure the volume in the graduated cylinder to the nearest 0.1 mL, and record as percent residue.

10.19.1 If the 5-mL graduated cylinder does not have graduations below 1 mL and the volume of liquid is less than 1 mL, prefill the cylinder with 1 mL of a heavy oil to allow a better estimate of the volume of the material recovered.

10.19.1.1 If a residue greater than expected is obtained, and the distillation was not purposely terminated before the EP, check whether adequate heat was applied towards the end of the distillation and whether conditions during the test conformed to those specified in Table 5. If not, repeat test.

NOTE 19 - The distillation residues of this test method for gasoline, kerosine, and distillate diesel are typically 0.9–1.2, 0.9–1.3, and 1.0–1.4 volume %, respectively.

NOTE 20 - The test method is not designed for the analysis of distillate fuels containing appreciable quantities of residual material (see 1.2).

10.19.2 Groups 1, 2, 3, and 4 - Record the volume in the 5-mL graduated cylinder, to the nearest 0.1 mL, as percent residue.

10.20 If the intent of the distillation is to determine the percent evaporated or percent recovered at a predetermined corrected temperature reading, modify the procedure to conform to the instructions described in Annex A4.

10.21 Examine the condenser tube and the side arm of the flask for waxy or solid deposits. If found, repeat the test after making adjustments described in Footnote A of Table 5.