ASTM D86 for distillation of petroleum products at atmospheric pressure

9. Calibration and Standardization

9.1 Temperature Measurement System - Temperature measurement systems using other than the specified mercury-in-glass thermometers shall exhibit the same temperature lag, emergent stem effect, and accuracy as the equivalent mercury-in-glass thermometer. Confirmation of the calibration of these temperature measuring systems shall be made at intervals of not more than six months, and after the system has been replaced or repaired.

9.1.1 The accuracy and the calibration of the electronic circuitry or computer algorithms, or both, shall be verified by the use of a standard precision resistance bench. When performing this verification, no algorithms shall be used to correct the temperature for lag and the emergent stem effect (see manufacturer's instructions).

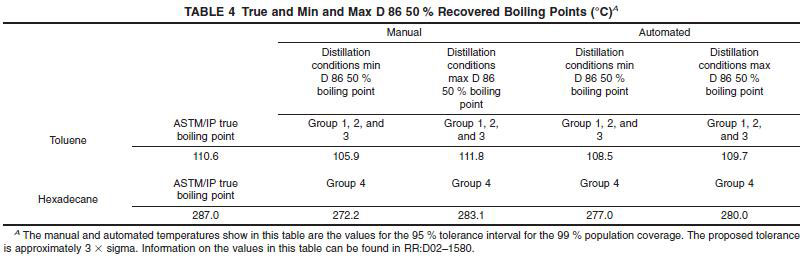

9.1.2 Verification of the calibration of temperature measuring devices shall be conducted by distilling toluene in accordance with Group 1 of this test method and comparing the 50 % recovered temperature with that shown in Table 4.

9.1.2.1 If the temperature reading is not within the values shown in Table 4 for the respective apparatus being used (see Note 10 and Table 4), the temperature measurement system shall be considered defective and shall not be used for the test.

NOTE 9 - Toluene is used as a verification fluid for calibration; it will yield almost no information on how well an electronic measurement system simulates the temperature lag of a liquid-in-glass thermometer.

9.1.2.2 Reagent grade toluene and hexadecane (cetane), conforming to the specifications of the Committee on Analytical Reagents of the American Chemical Society, shall be used. However, other grades may also be used, provided it is first ascertained that the reagent is of sufficient purity to permit its use without lessening the accuracy of the determination.

NOTE 10 - At 101.3 kPa, toluene is shown in reference manuals as boiling at 110.6°C when measured using a partial immersion thermometer. Because this test method uses thermometers calibrated for total immersion, the results typically will be lower and, depending on the thermometer and the situation, may be different for each thermometer. At 101.3 kPa, hexadecane is shown in reference manuals as boiling at 287.0°C when measured using a partial immersion thermometer. Because this test method uses thermometers calibrated for total immersion, the results typically will be lower, and, depending on the thermometer and the situation, may be different for each thermometer.

9.1.3 A procedure to determine the magnitude of the temperature lag is described in Annex A3.

9.1.4 A procedure to emulate the emergent stem effect is described in Appendix X4.

9.1.5 To verify the calibration of the temperature measurement system at elevated temperatures, use hexadecane. The temperature measurement system shall indicate, at 50% recovered, a temperature comparable to that shown in Table 4 for the respective apparatus under Group 4 distillation conditions.

NOTE 11 - Because of the high melting point of hexadecane, Group 4 verification distillations will have to be carried out with condenser temperatures >20°C.

9.2 Automated Method:

9.2.1 Level Follower - For an automated distillation apparatus, the level follower/recording mechanism of the apparatus shall have a resolution of 0.1 mL or better with a maximum error of 0.3 mL between the 5 and 100 mL points. The calibration of the assembly shall be verified in accordance with manufacturer's instructions at intervals of not more than three months and after the system has been replaced or repaired.

NOTE 12 - The typical calibration procedure involves verifying the output with the receiver containing 5 and 100 mL of material respectively.

9.2.2 Barometric Pressure - At intervals of not more than six months, and after the system has been replaced or repaired, the barometric reading of the instrument shall be verifiedagainst a barometer, as described in 6.6.